SCREW COMPRESSORS SPECIALIST | Customer Satisfaction Is Our Goal | SCS is a WORLDWIDE leader of Screw Compressors

* In Shop Overhaul *Machine Shop In House *Cast Iron Housing Repair *Balancing *Industrial Hard Chrome Rotor and Seal Journal *Industrial Hard Chrome Piston Rod *Laser Alignment *Fast Turn Around Time *OEM Parts *Fast Respond *OEM Paint or Customer Specification *Emergency 24-7 Service *New Compressors *Preventive Maintenance Vibration Analysis Oil Analysis *Remanufactured Compressors *Exchange Program

Frick TDSH and TDSB Screw Compressors SERVICE REPAIR OVERHAUL

Screw Compressors Service Specializes in the overhaul and repair of all model TDSH AND TDSB Compressors.

Our facility can handle any size TDSH compressor. Frick TDSH compressor units are designed to handle multiple applications and require expertise when it comes to the repair and overhaul of this rotating equipment. SCS handles a wide range of customers within the United States along with supporting multiple contractors nationwide. With over 35 years of specializing in screw compressors SCS has a vast knowledge of the compressor and packages associated to it. End users only need to make one phone call or email whenever in need of assistance.

Contact Information

SCOTT RISTER

scottr@screwcompressorsspecialist.com

210-330-7443

Page 2a

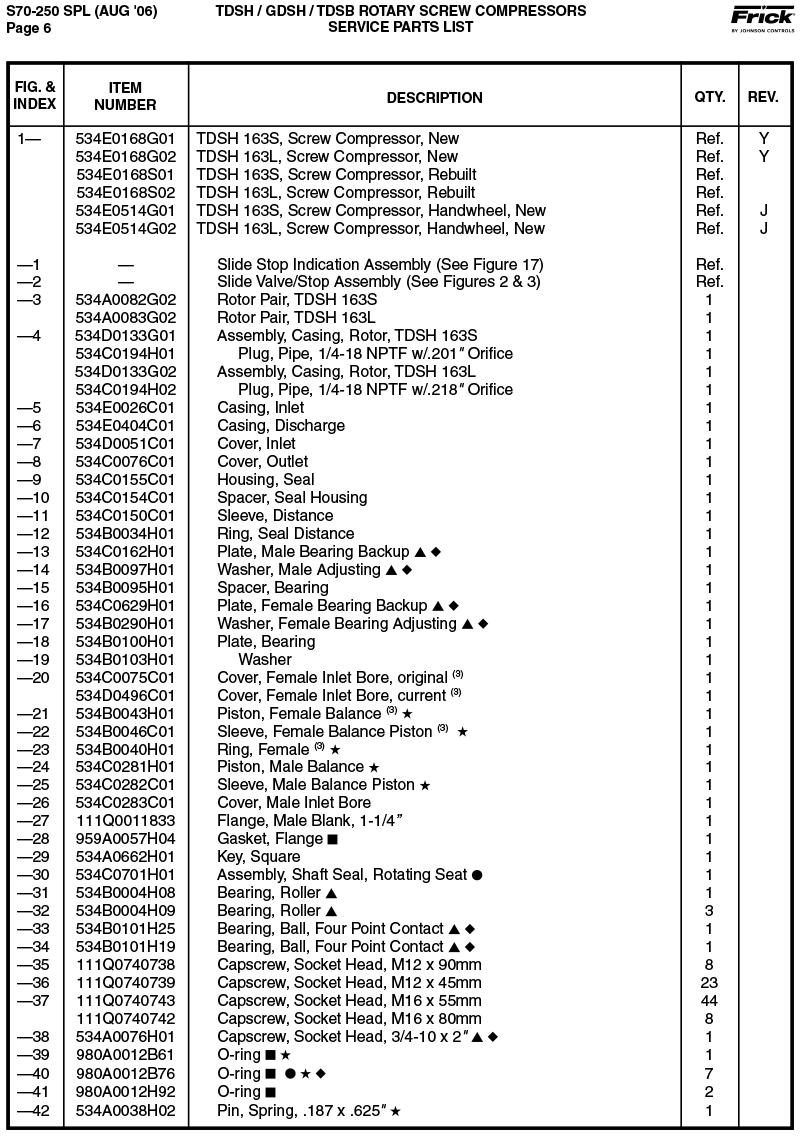

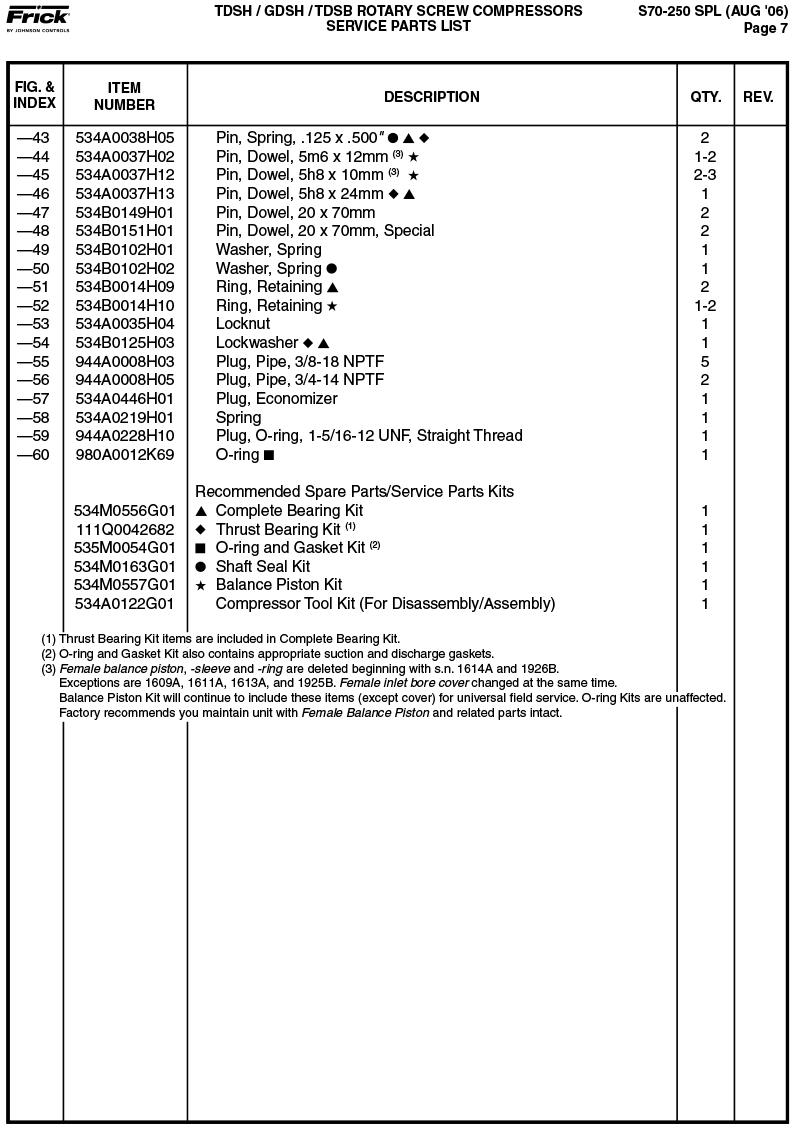

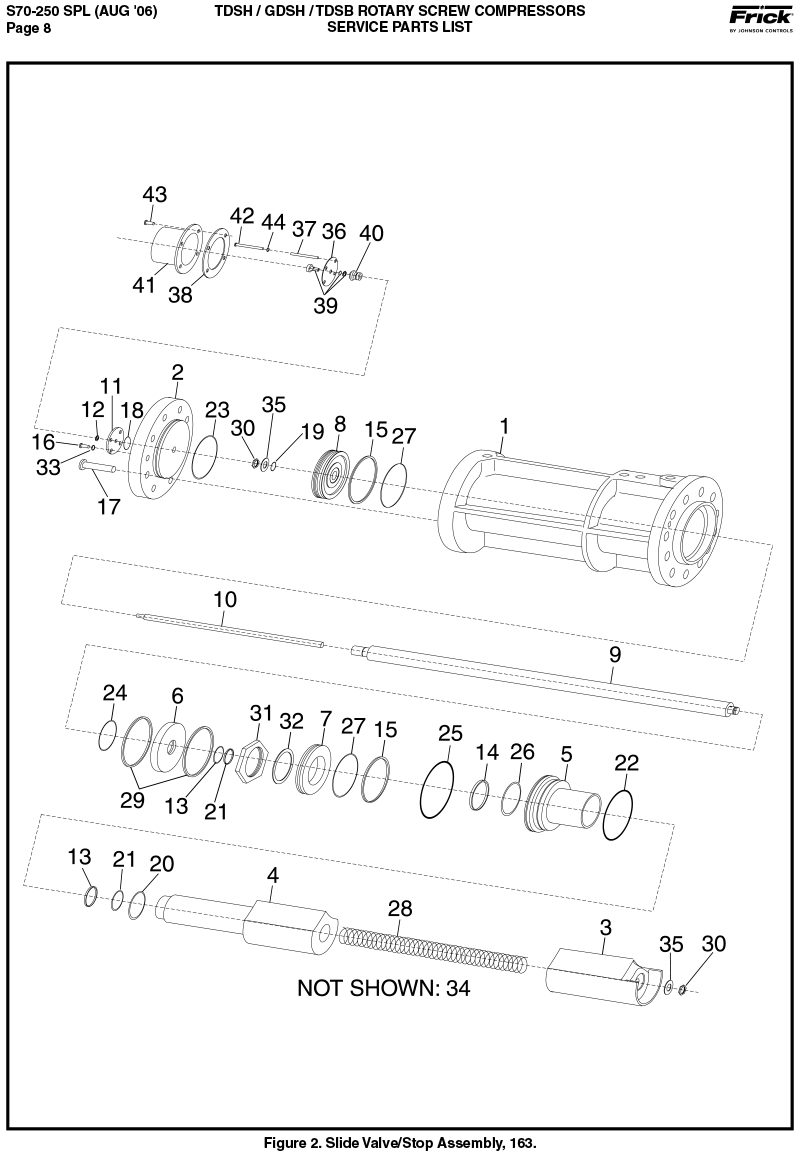

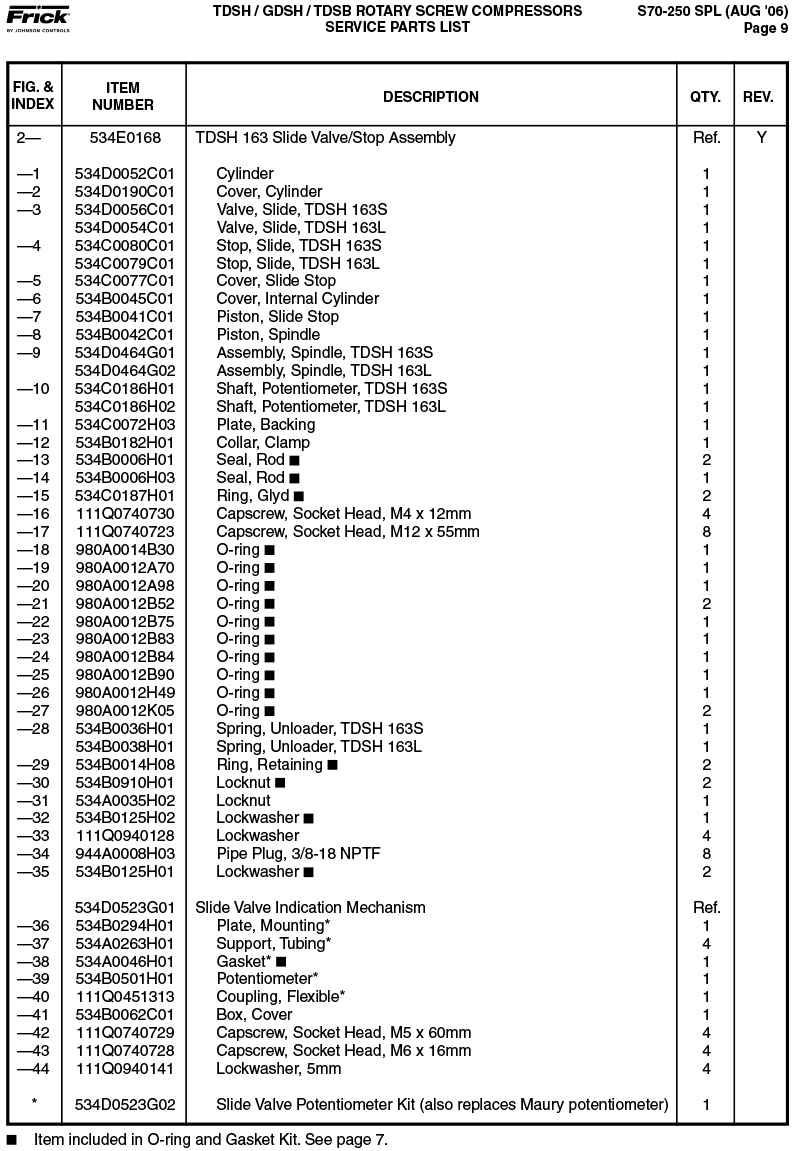

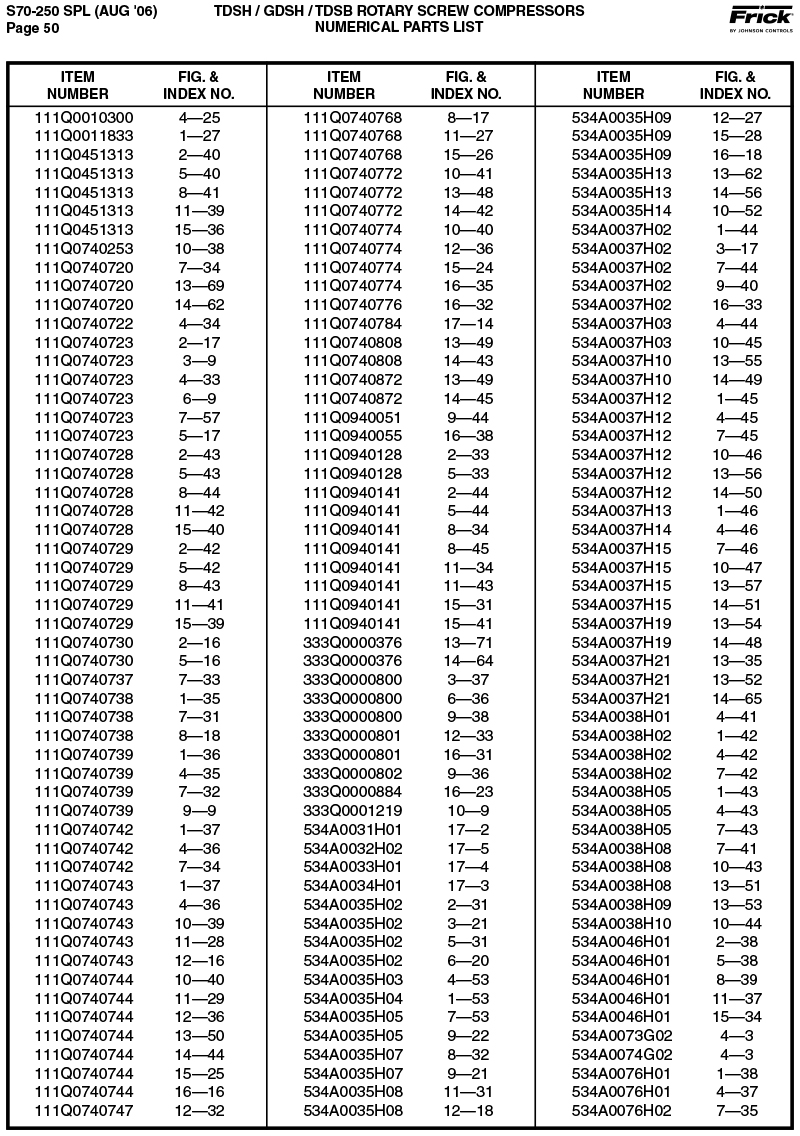

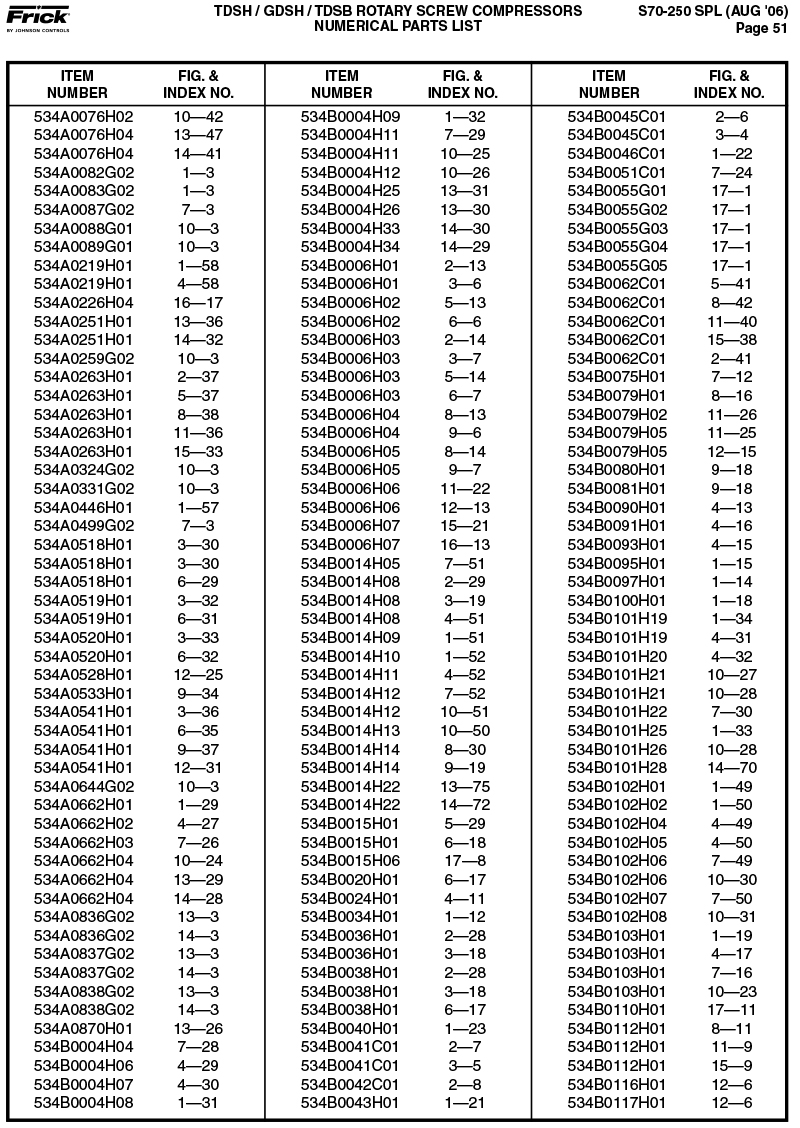

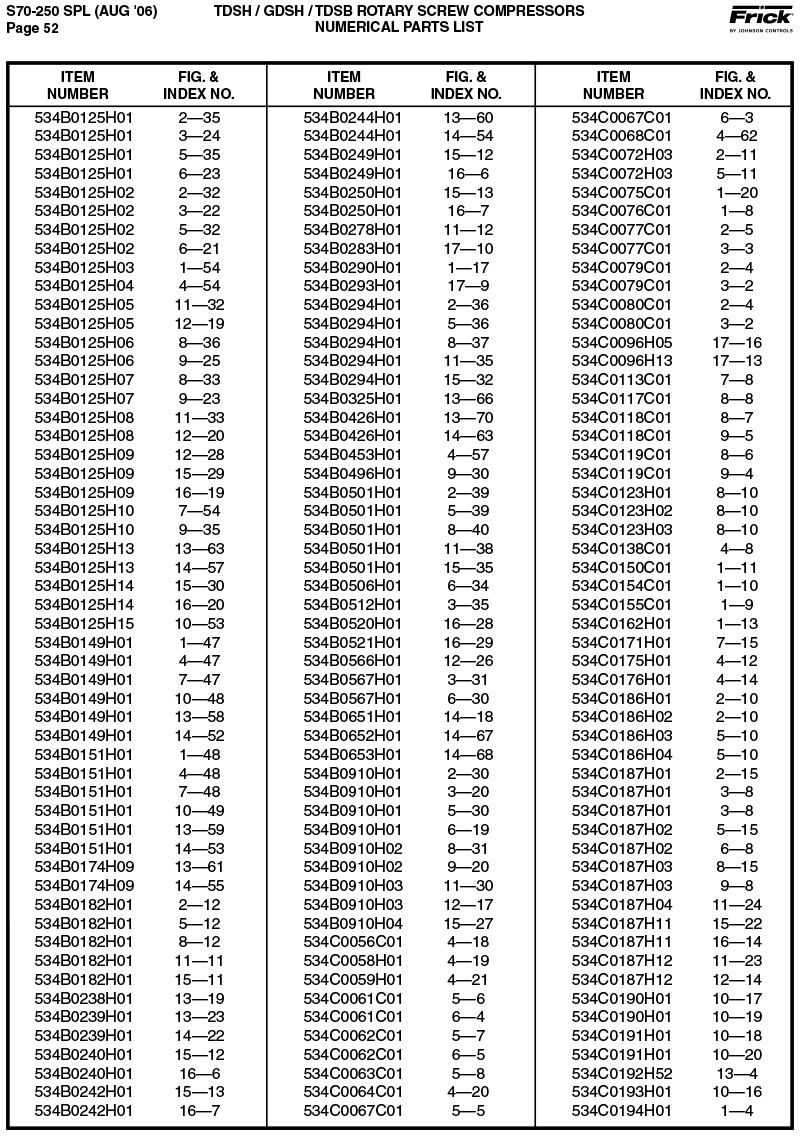

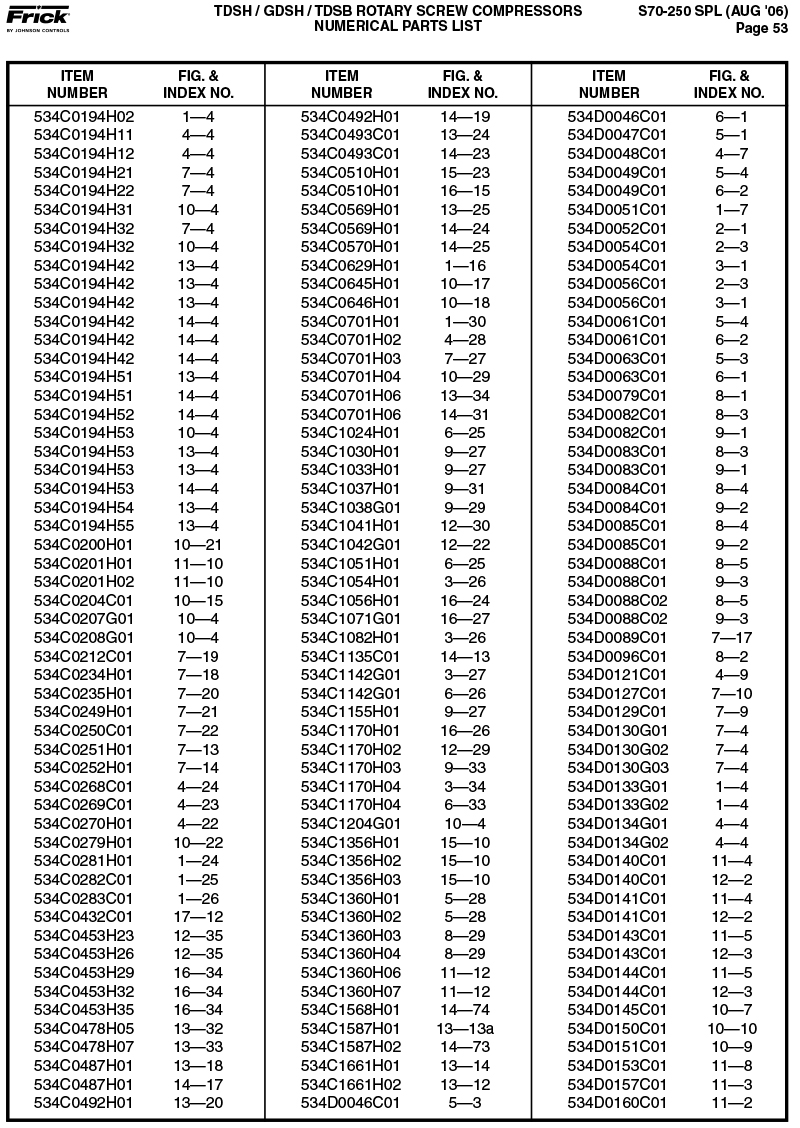

HOW TO USE SERVICE PARTS LIST

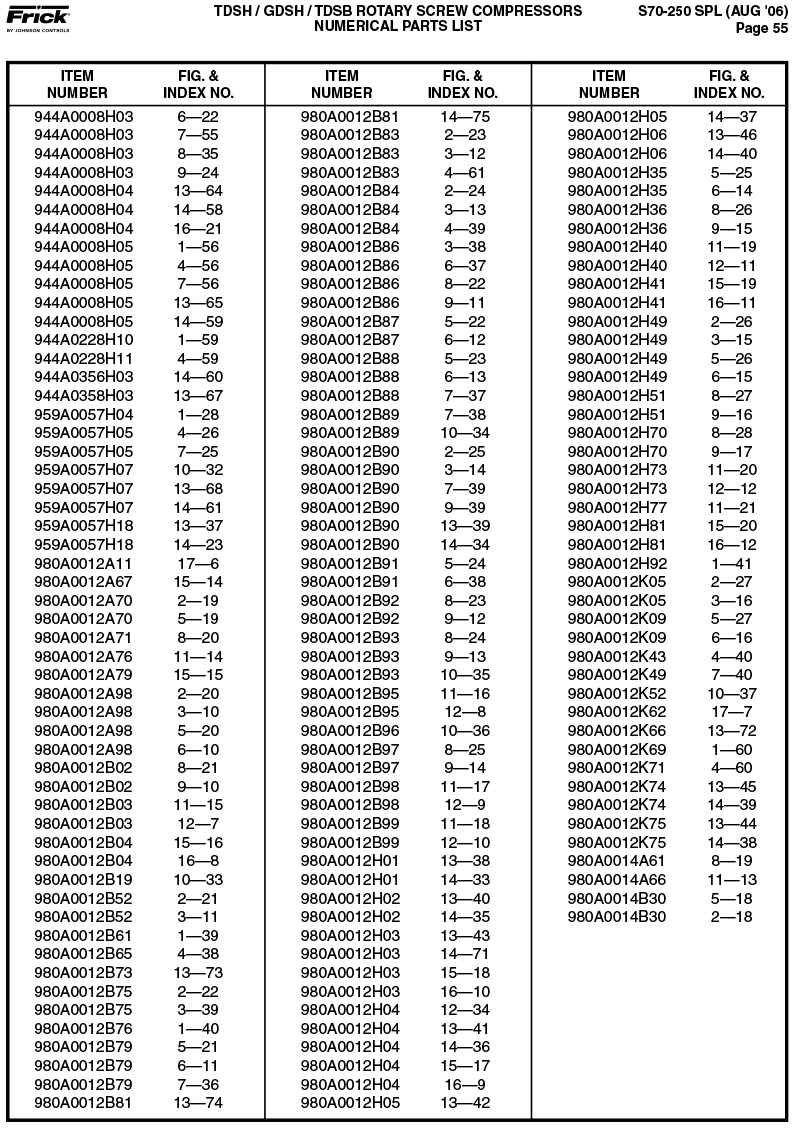

This Service Parts List is for standard Frick TDSH / GDSH / TDSB Rotary Screw Compressors, Models 163 through 355. GDSH models are the same as TDSH 163-283 with the exeption of a class 300 suction flange rotor housing. Compressors built with special options, modifications, or conversions are not taken into consideration. This Service Parts List provides identification for detail parts by Figure and Index Number, Item Number and Description. To determine correct replacement, locate item on Figure 1, 2, etc., note index number, refer to corresponding index number in parts list for item number and description. Quantity per assembly is located in QTY. column. Unit of measure is always “each” unless specified otherwise in Quantity column. When Ref. is in QTY. column, this means that the Item Number is for reference only and is not necessarily a service replacement part. Contact Baltimore Parts Center for more information. REV. (Revision) column tells the level of the engineering drawing used here.

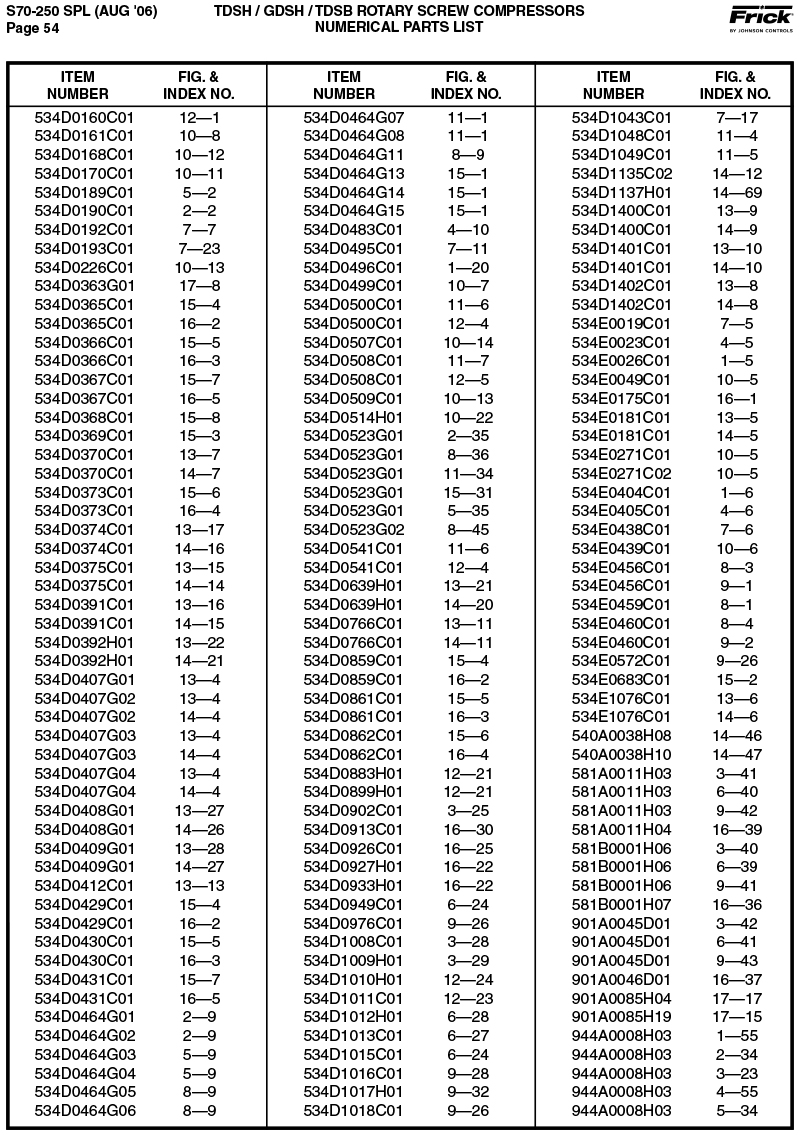

The Numerical Parts List can be used to locate a specific item in the Service Parts List. Look for the part by Frick Item Number and it will refer you to the Figure and Index Number where it is located. Abbreviations found in this manual include:

A/R................... As Required

N/A................... Not Available

NOTE: PLEASE PROVIDE FRICK ORDER NUMBER, MODEL NUMBER, AND SERIAL NUMBER WHEN REQUESTING A QUOTATION OR PLACING AN ORDER. FAILURE TO INCLUDE THIS INFORMATION MAY DELAY PROCESSING OF YOUR REQUEST. MODEL AND SERIAL NUMBER PLATE IS FOUND ON THE ROTOR CASING ASSEMBLY.

Page 2b

TABLE OF CONTENTS

HOW TO USE SERVICE PARTS LIST page..2

RECOMMENDED SPARE PARTS - CURRENT DESIGN page..3

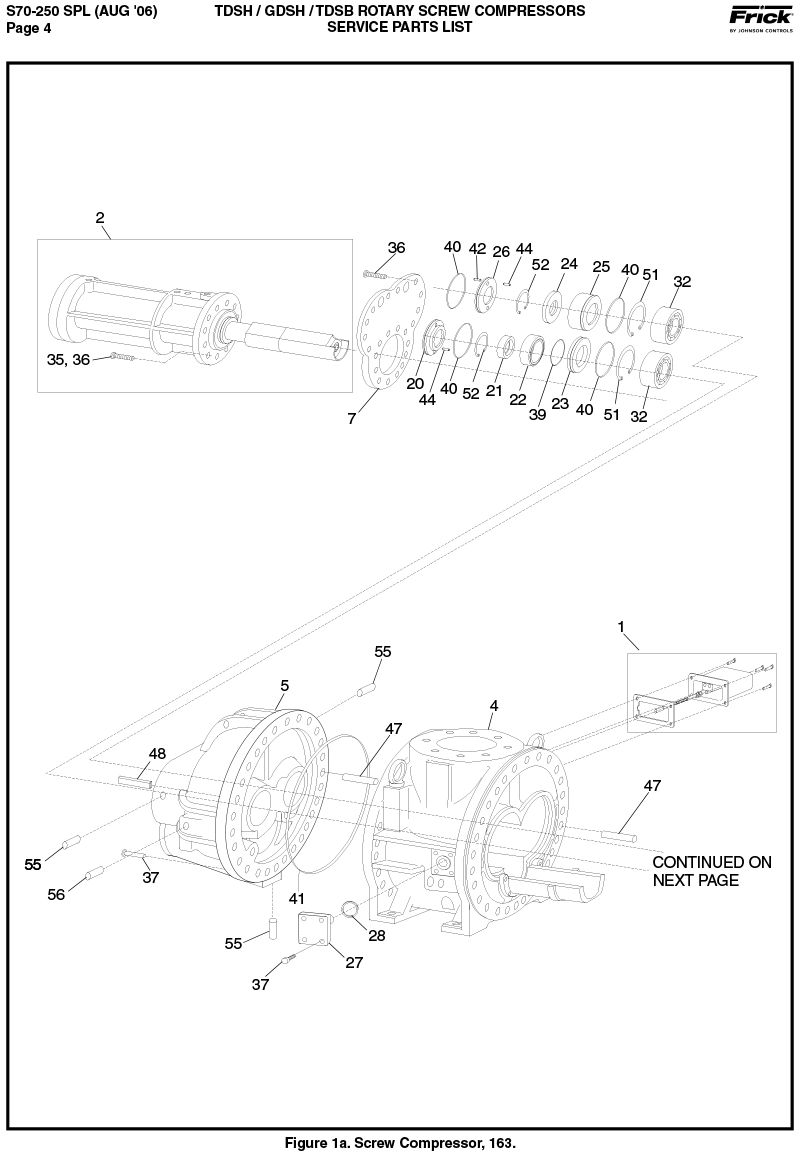

Figure 1a. Screw Compressor, 163 page..4

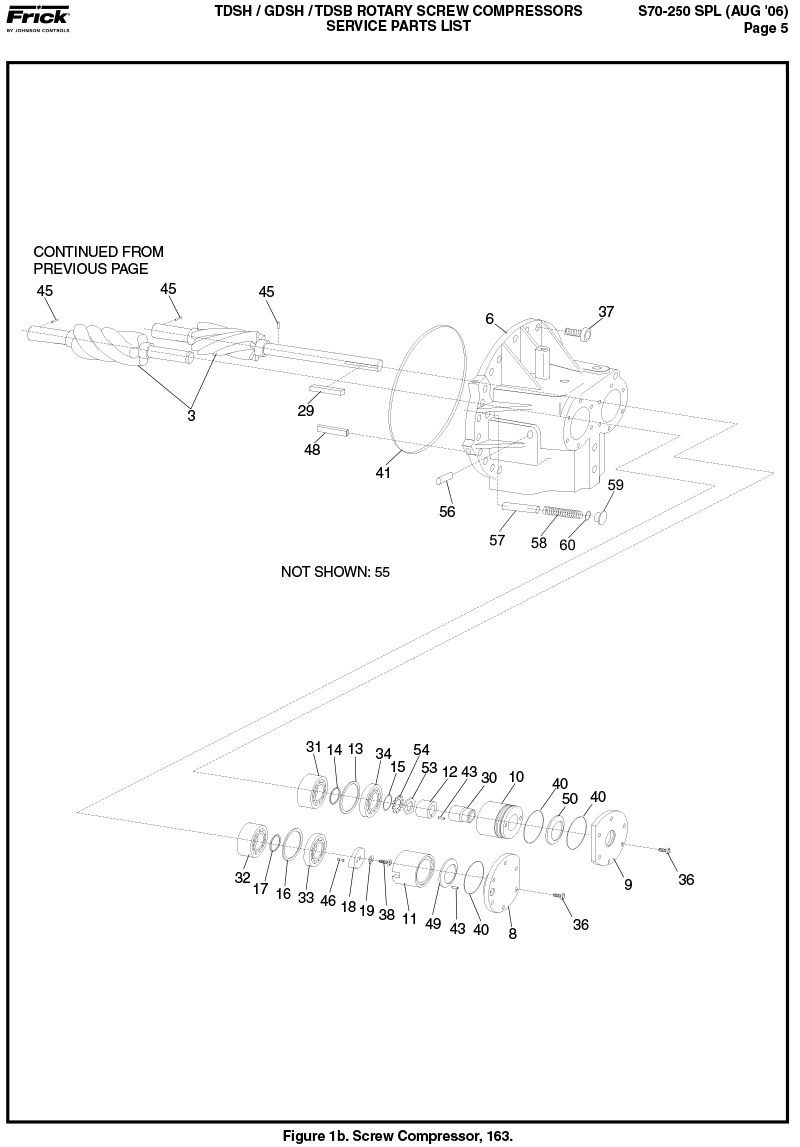

Figure 1b. Screw Compressor, 163 page..5

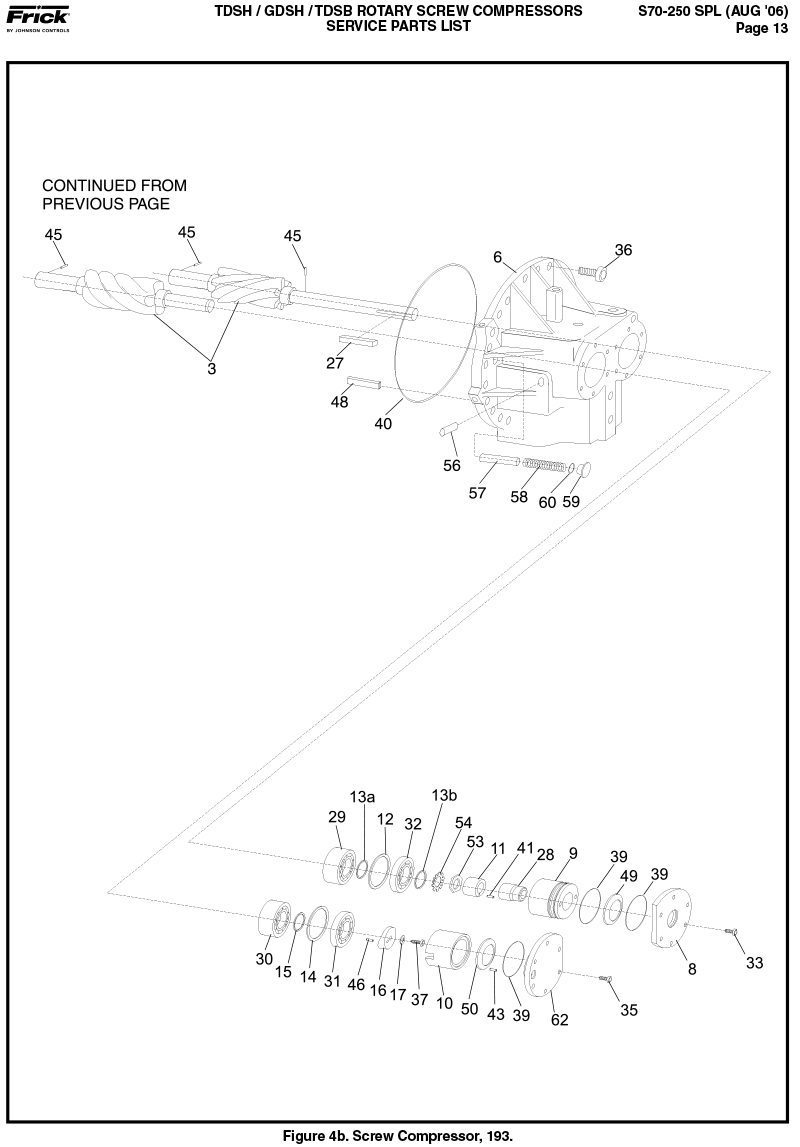

Figure 2. Slide Valve/Stop Assembly, 163 page..8

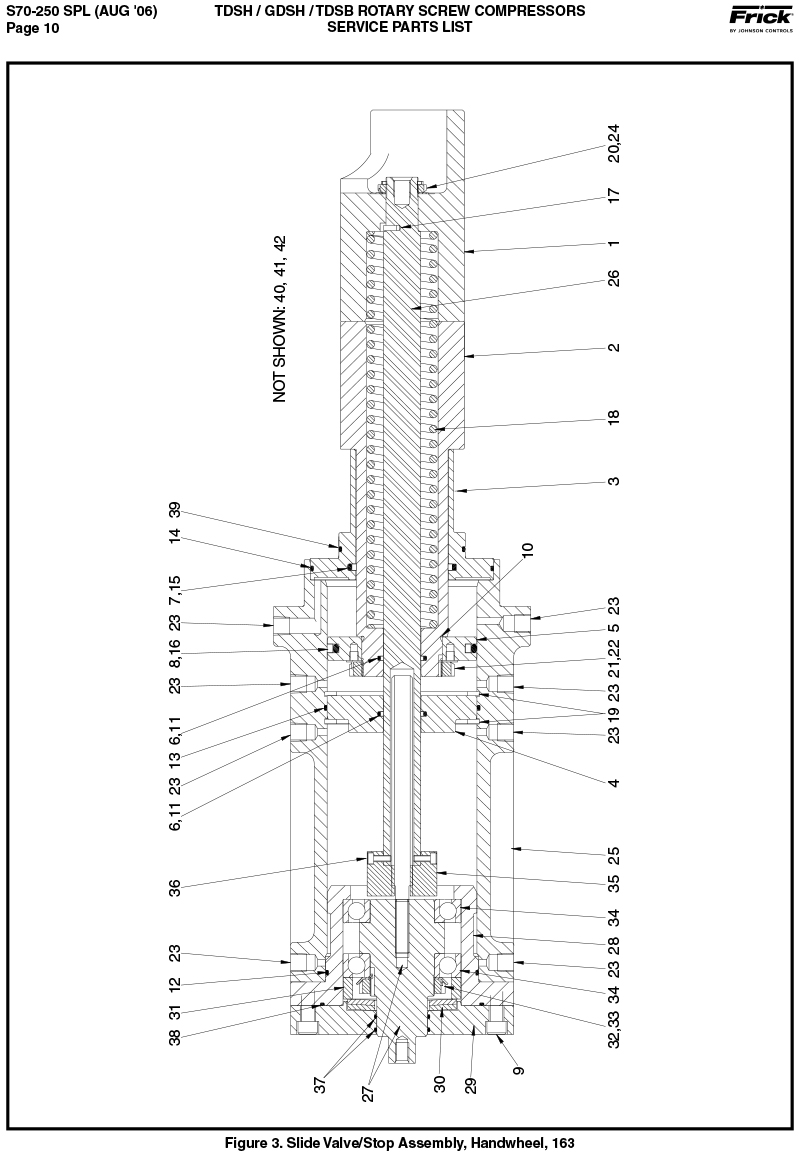

Figure 3. Slide Valve/Stop Assembly, Handwheel, 163 page..10

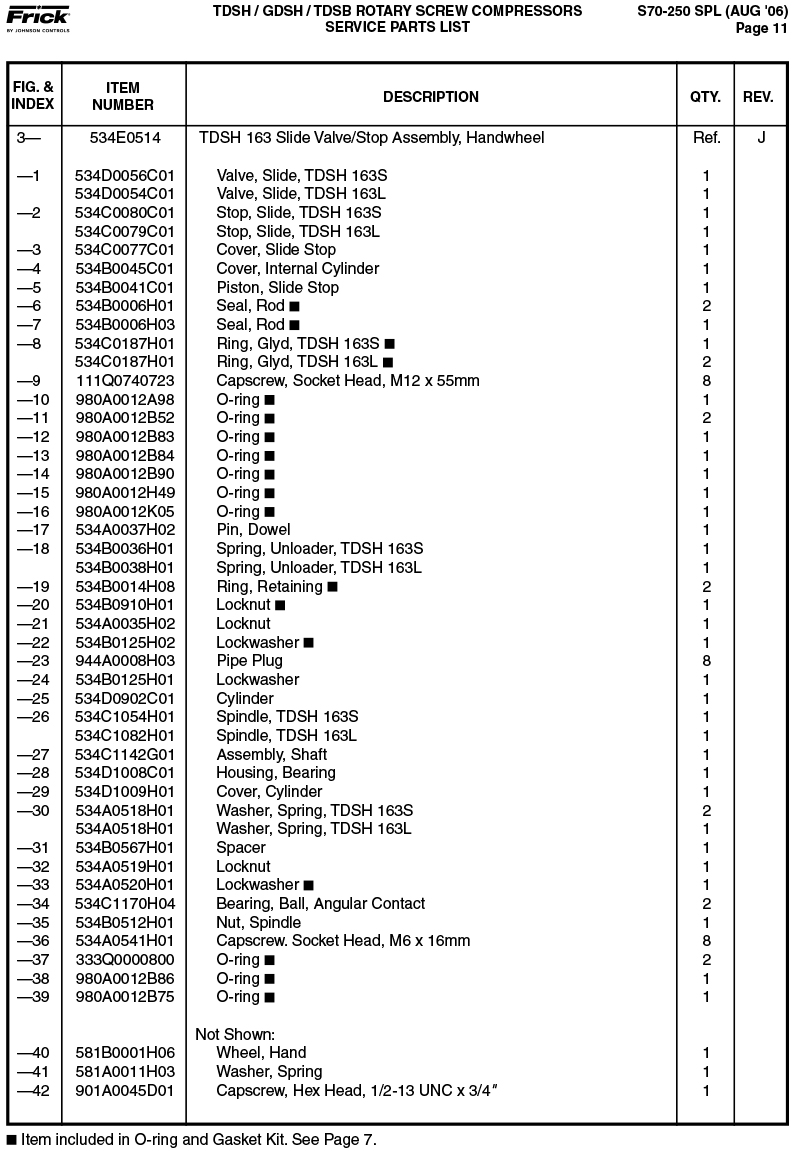

Figure 4a. Screw Compressor, 193 page..12

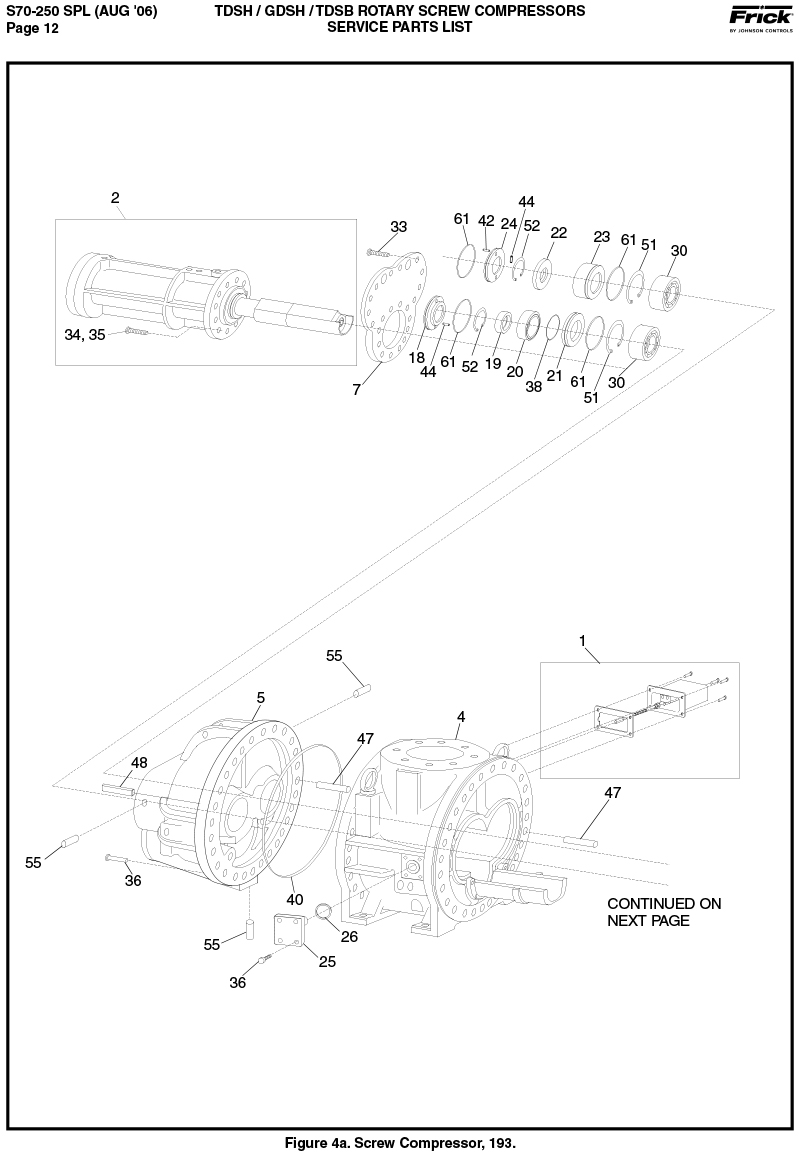

Figure 4b. Screw Compressor, 193 page..13

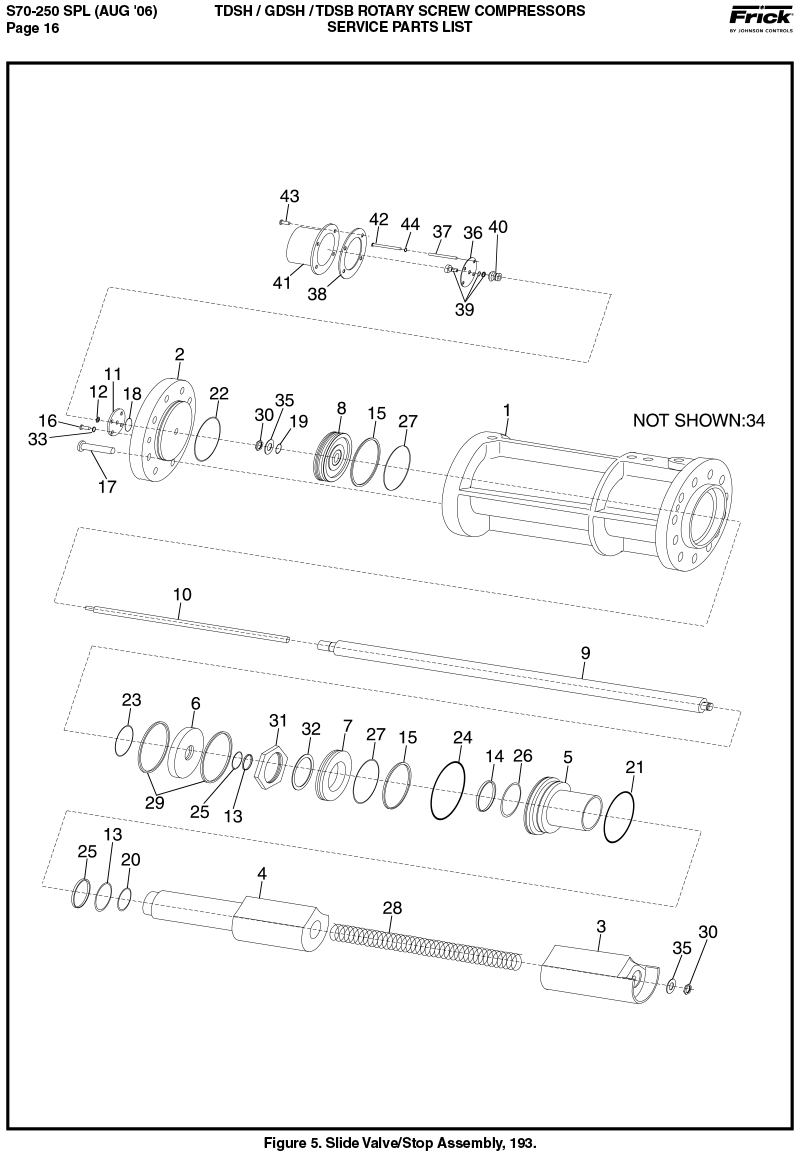

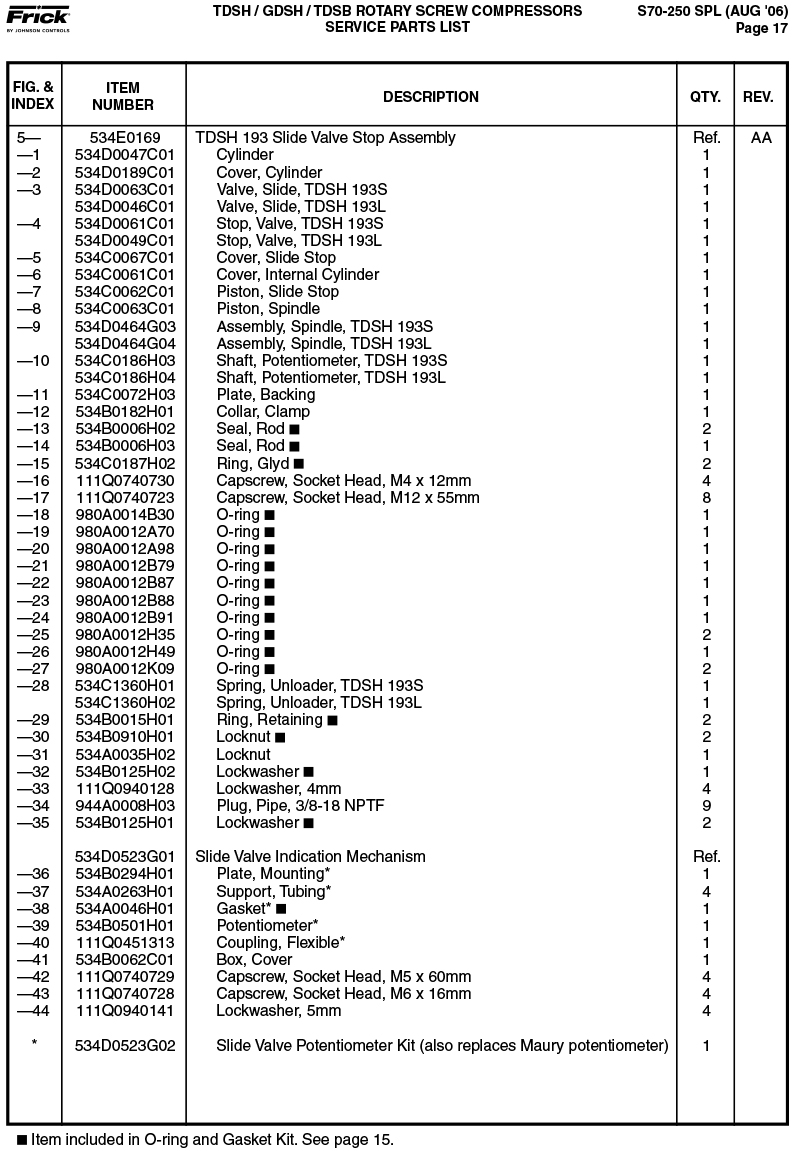

Figure 5. Slide Valve/Stop Assembly, 193 page..16

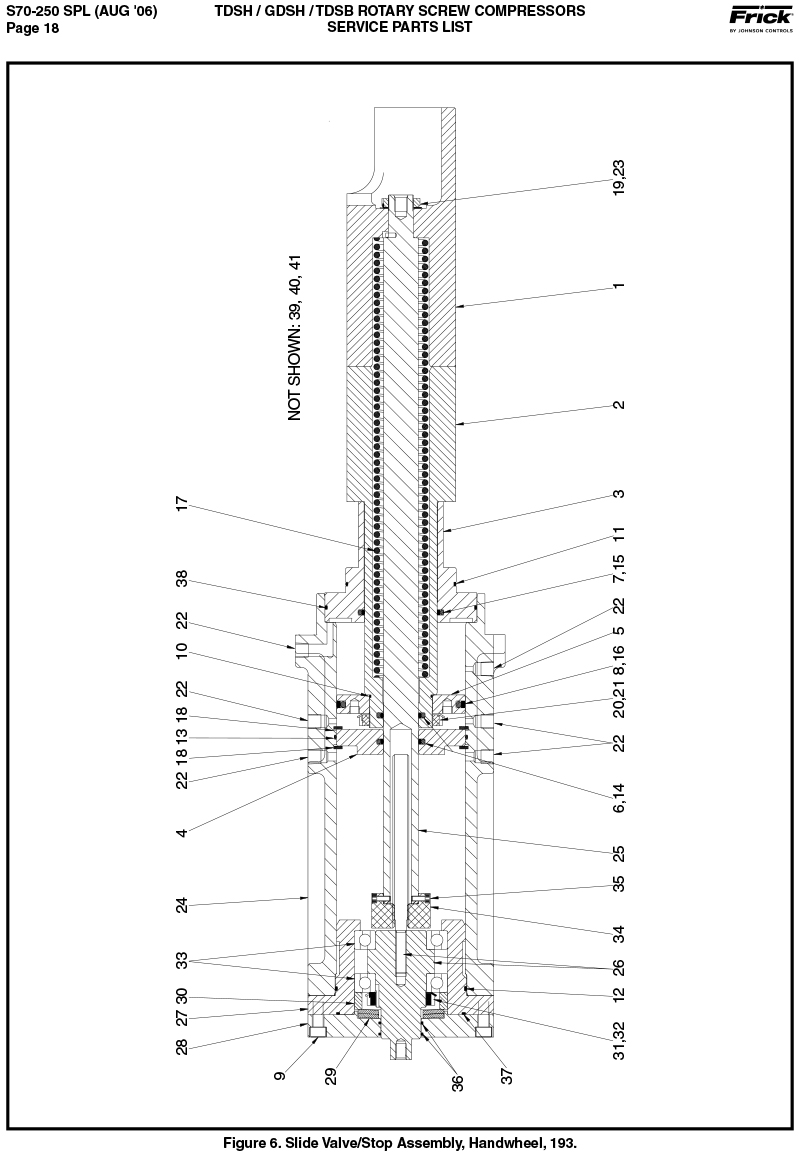

Figure 6. Slide Valve/Stop Assembly, Handwheel, 193 page..18

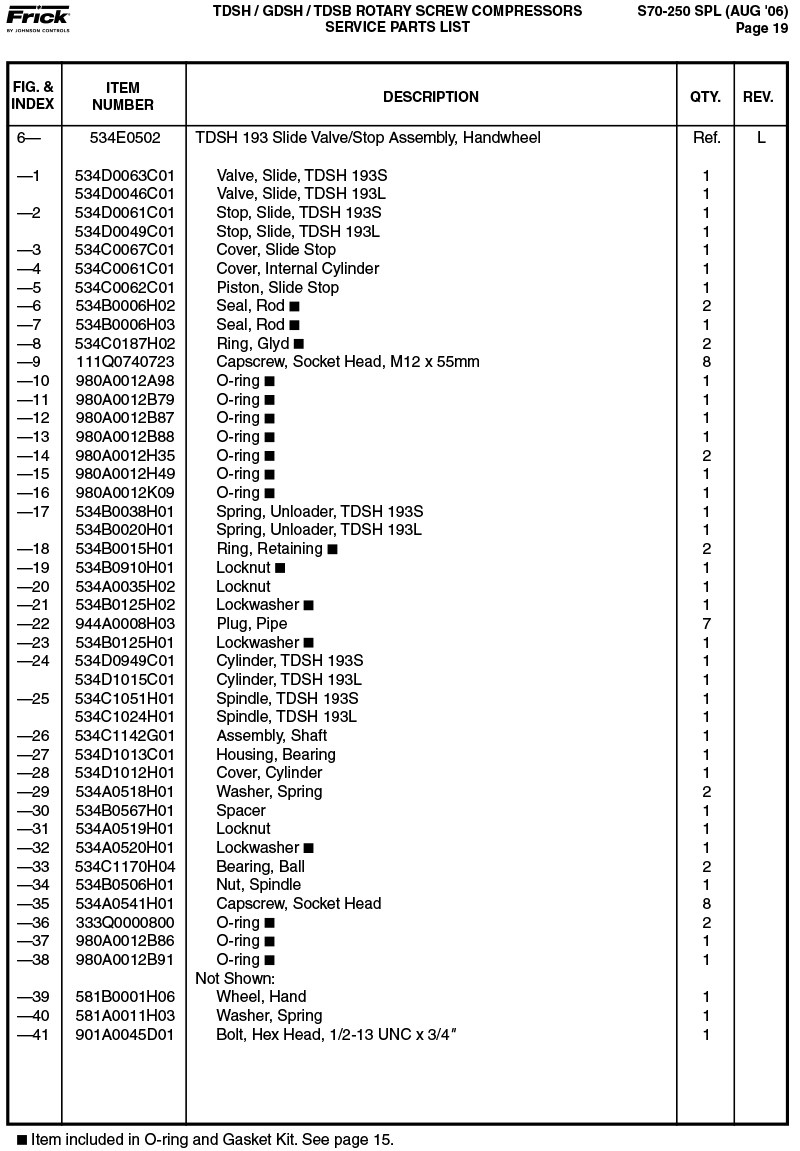

Figure 7a. Screw Compressor, 233 page..20

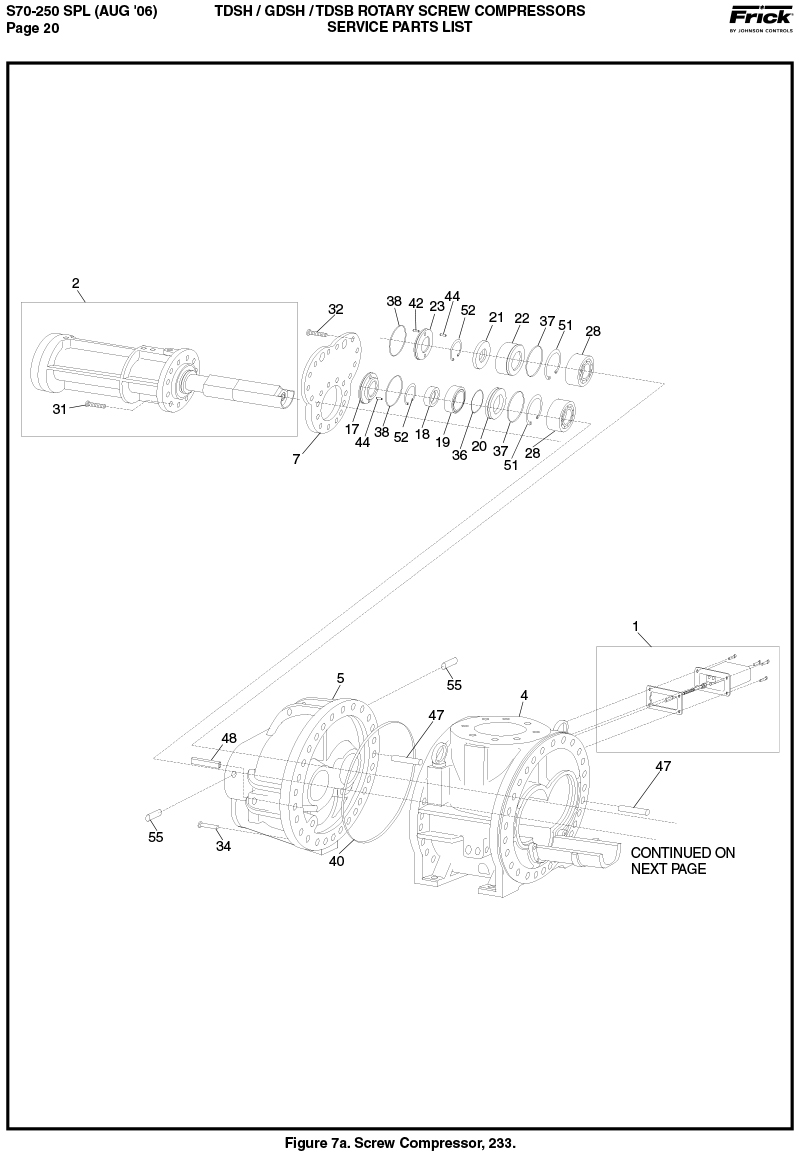

Figure 7b. Screw Compressor, 233 page..21

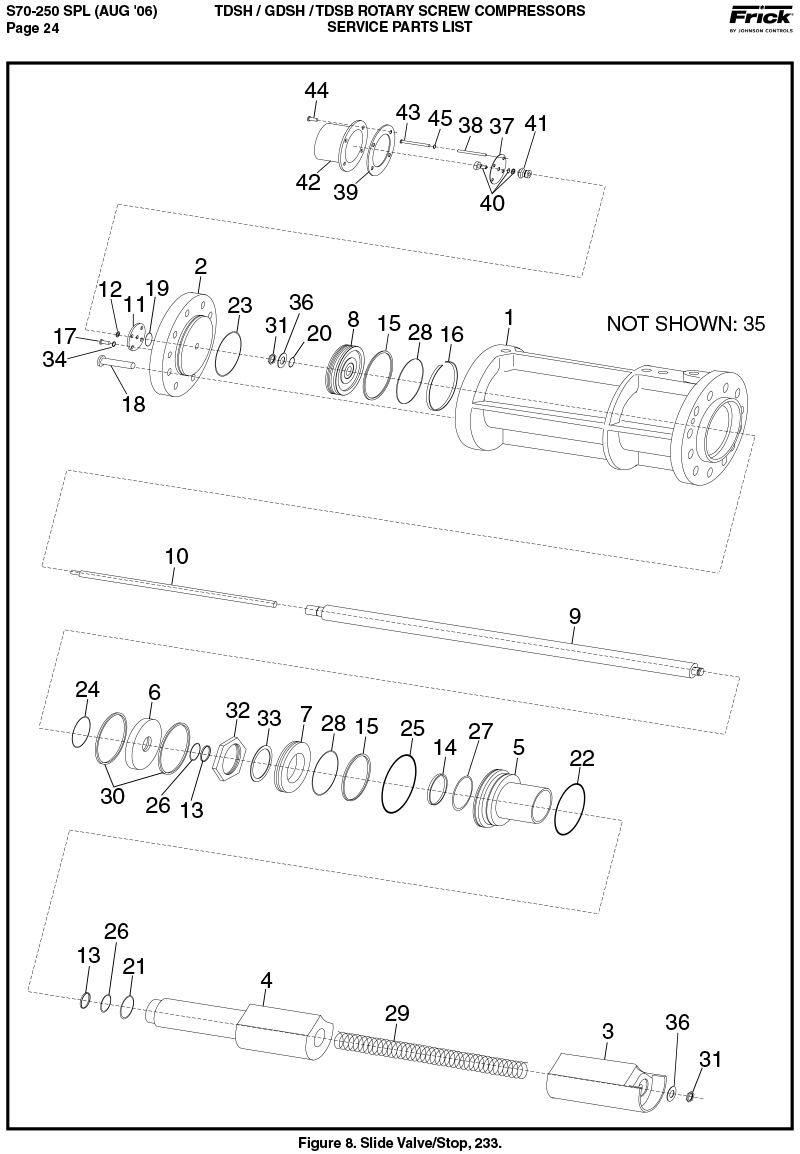

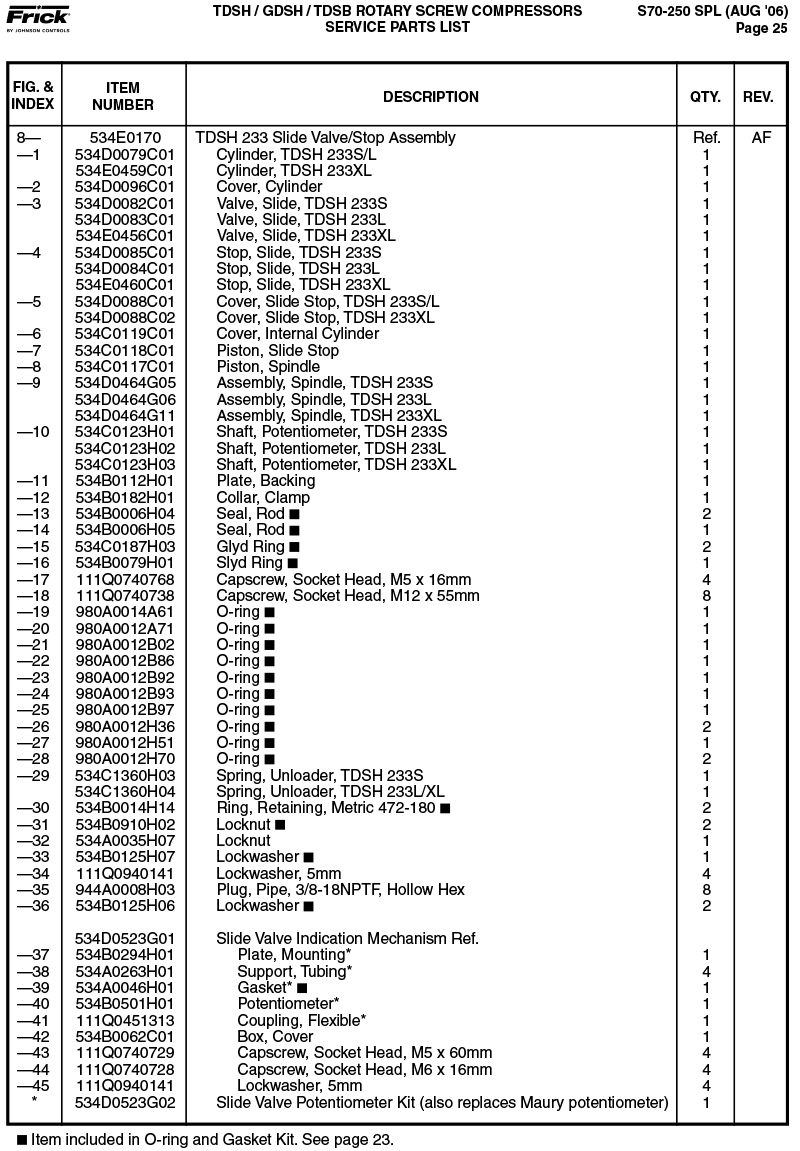

Figure 8. Slide Valve/Stop, 233 page..24

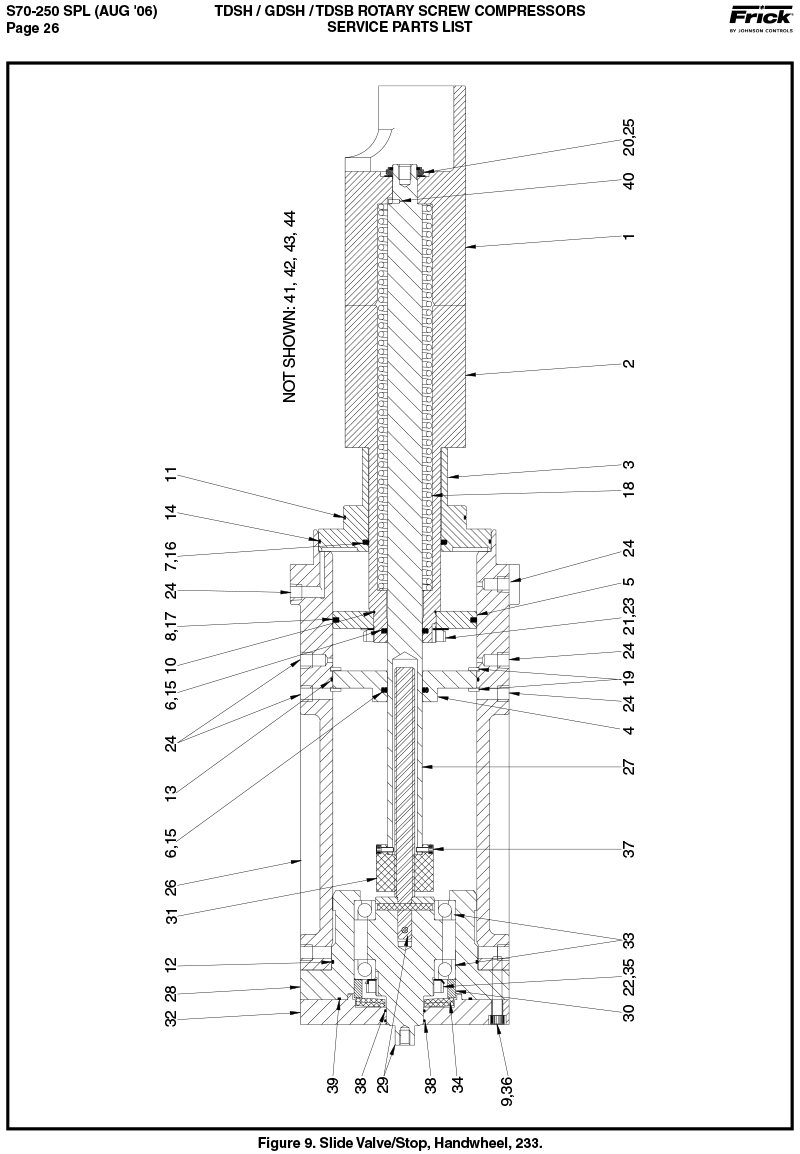

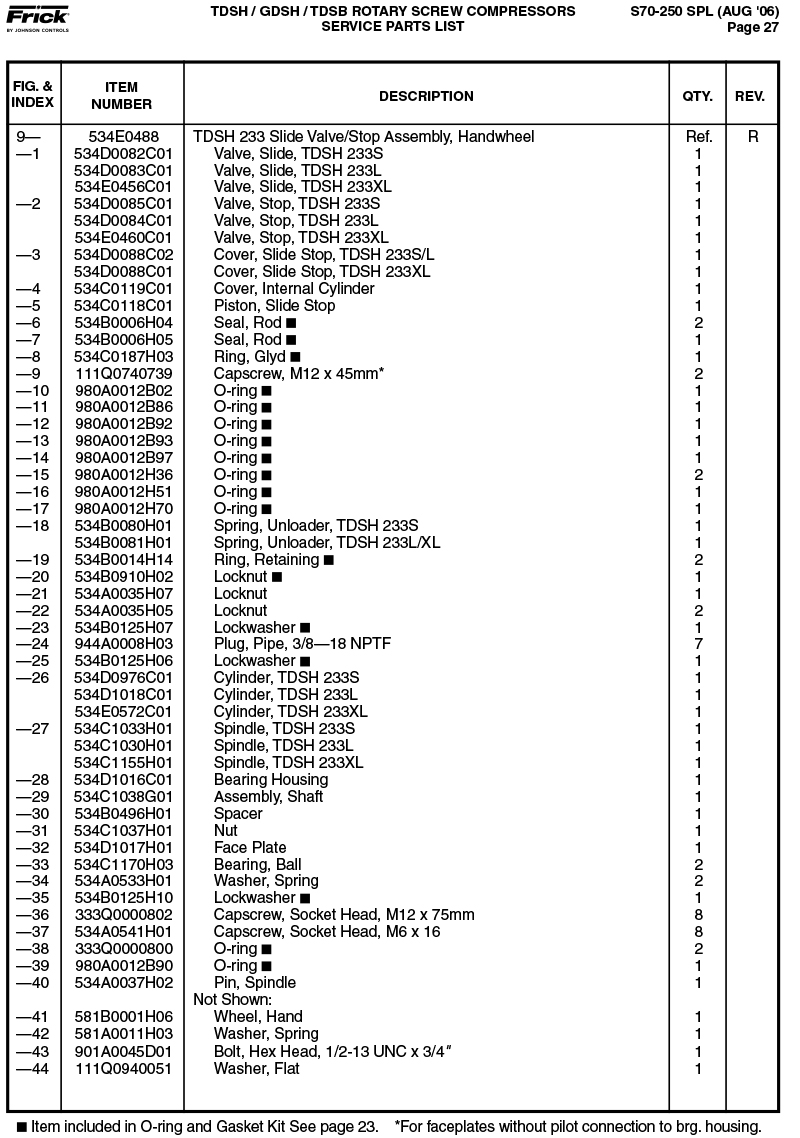

Figure 9. Slide Valve/Stop, Handwheel, 233 page..26

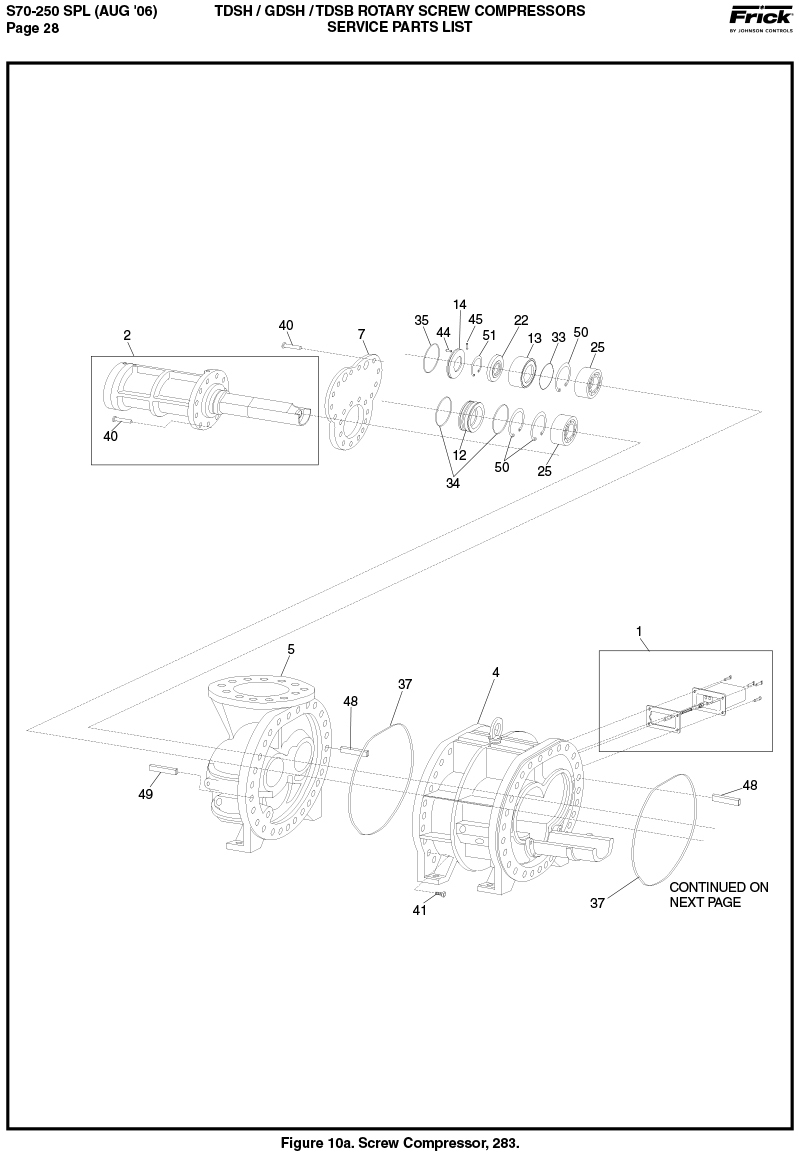

Figure 10a. Screw Compressor, 283 page..28

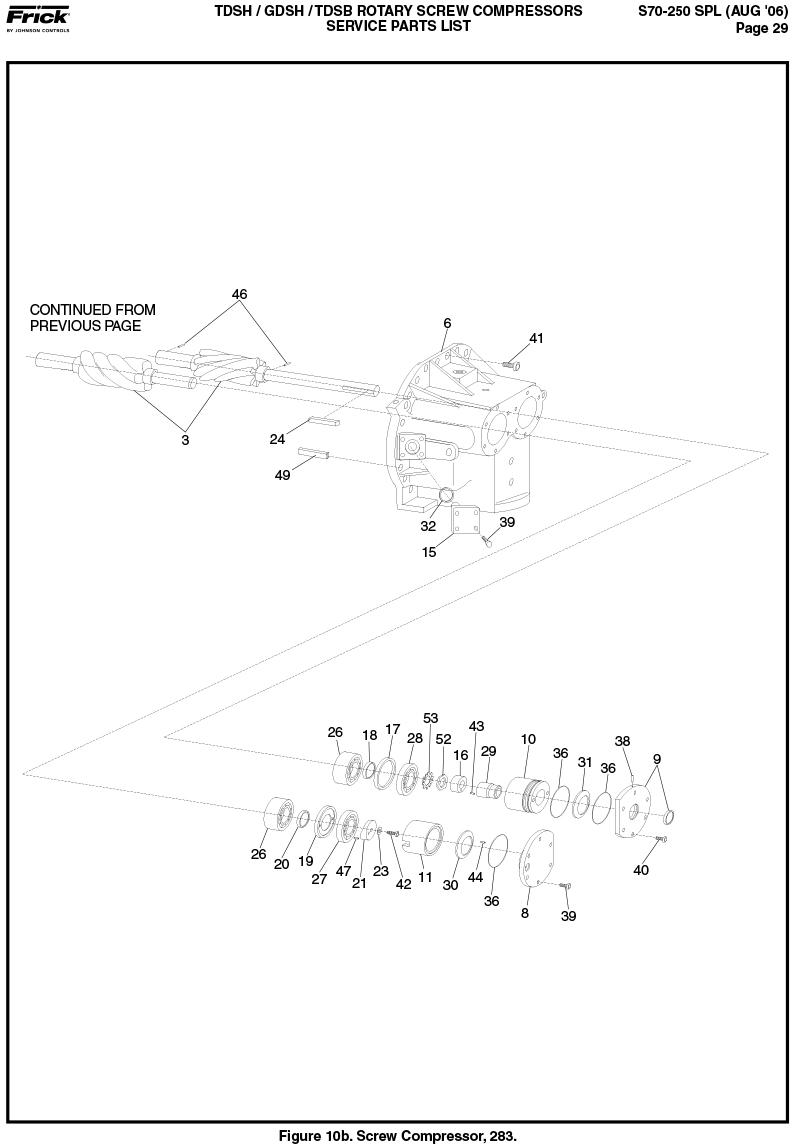

Figure 10b. Screw Compressor, 283 page..29

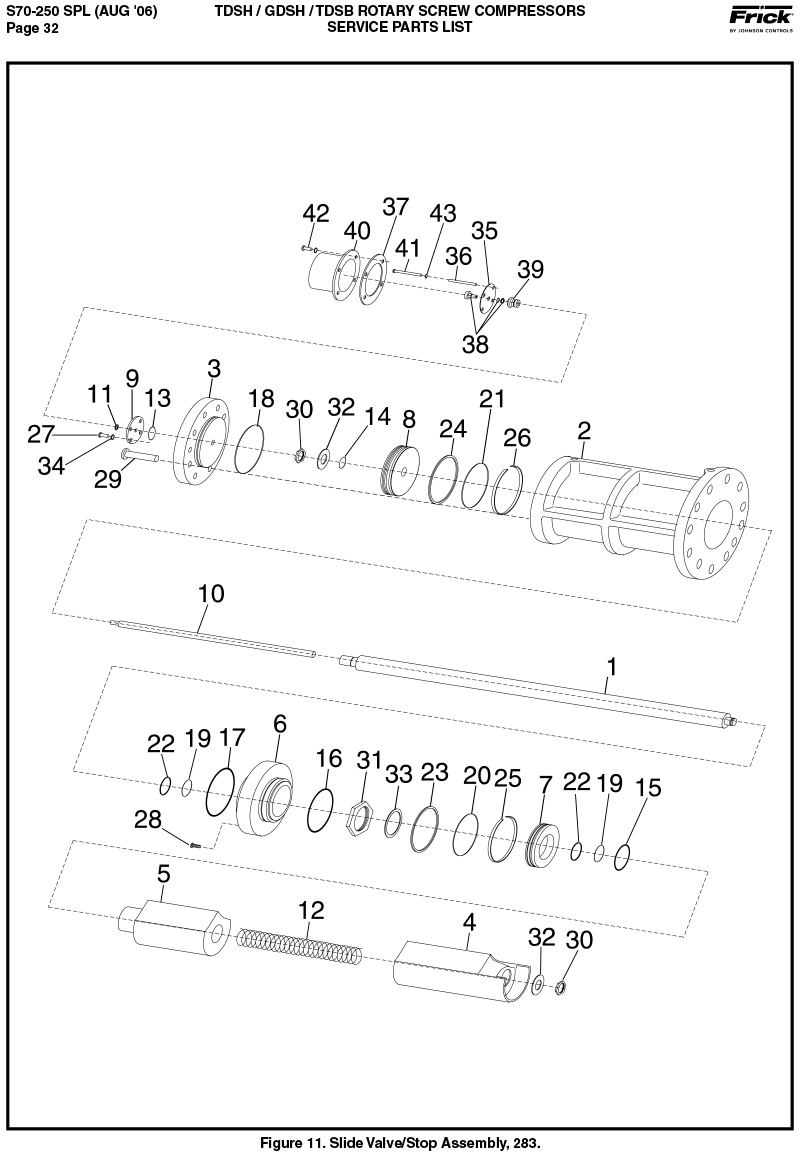

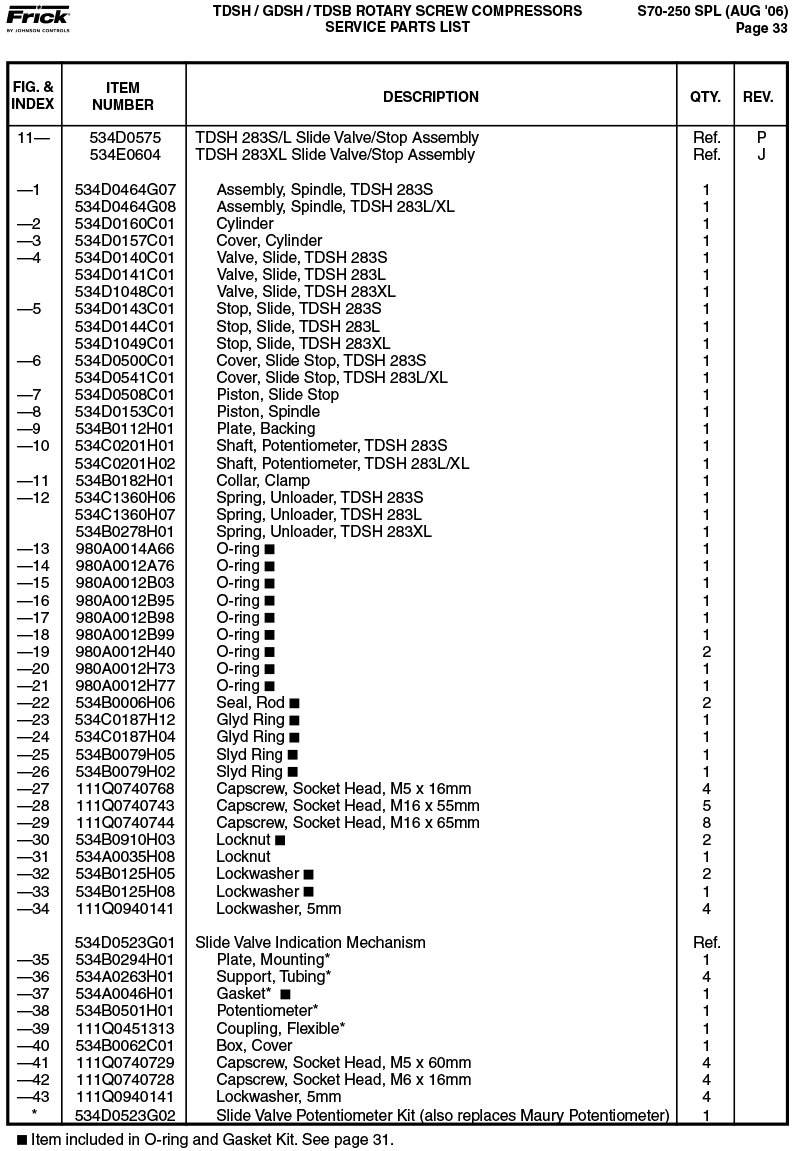

Figure 11. Slide Valve/Stop Assembly, 283 page..32

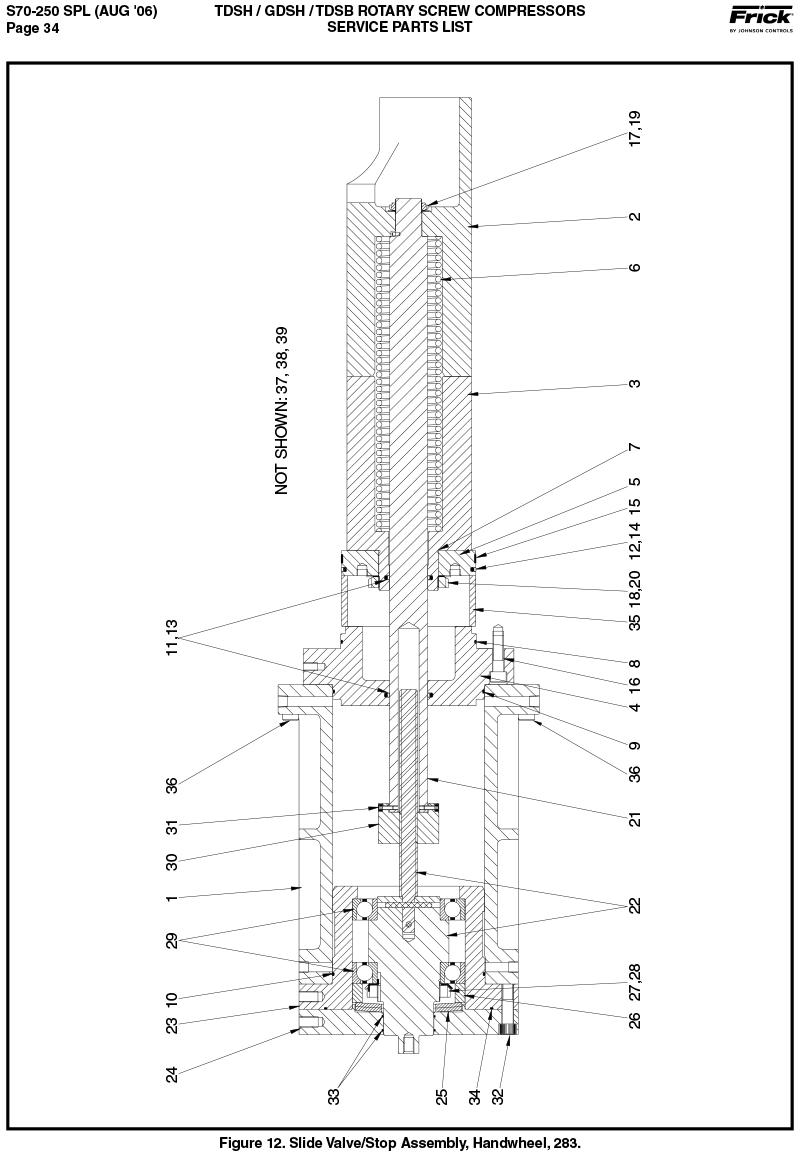

Figure 12. Slide Valve/Stop Assembly, Handwheel, 283 page..34

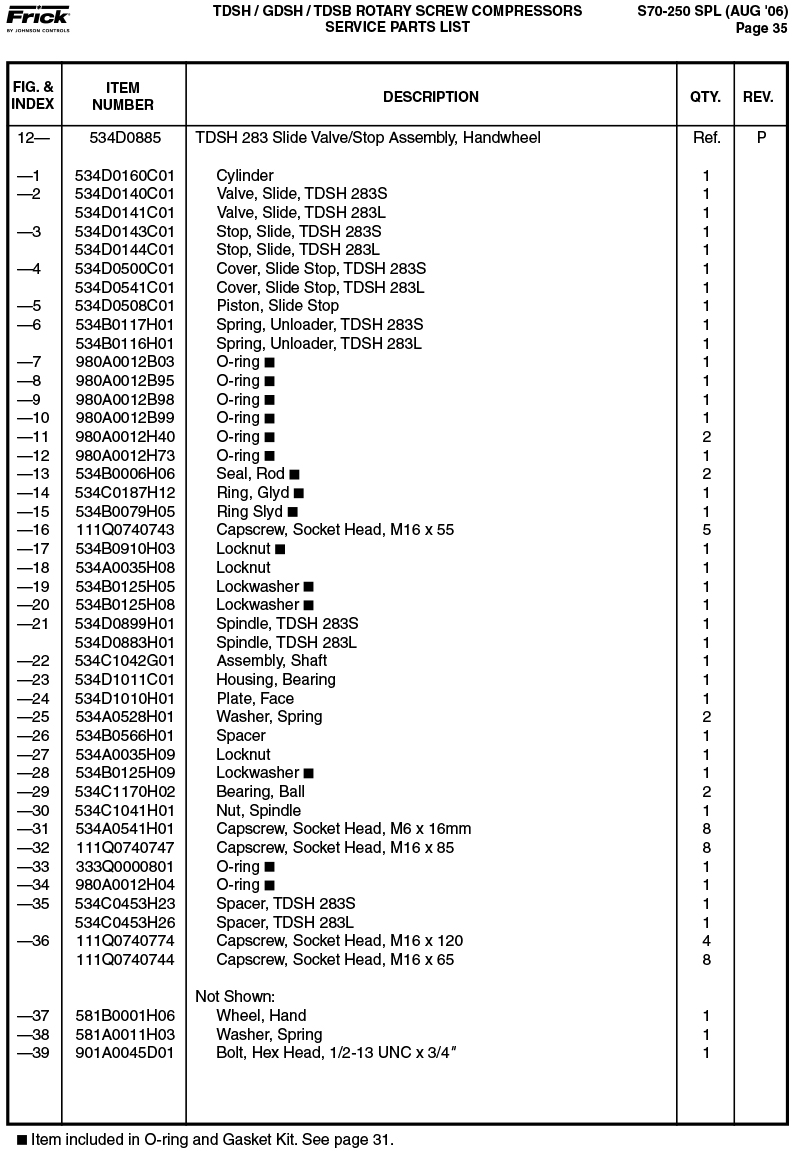

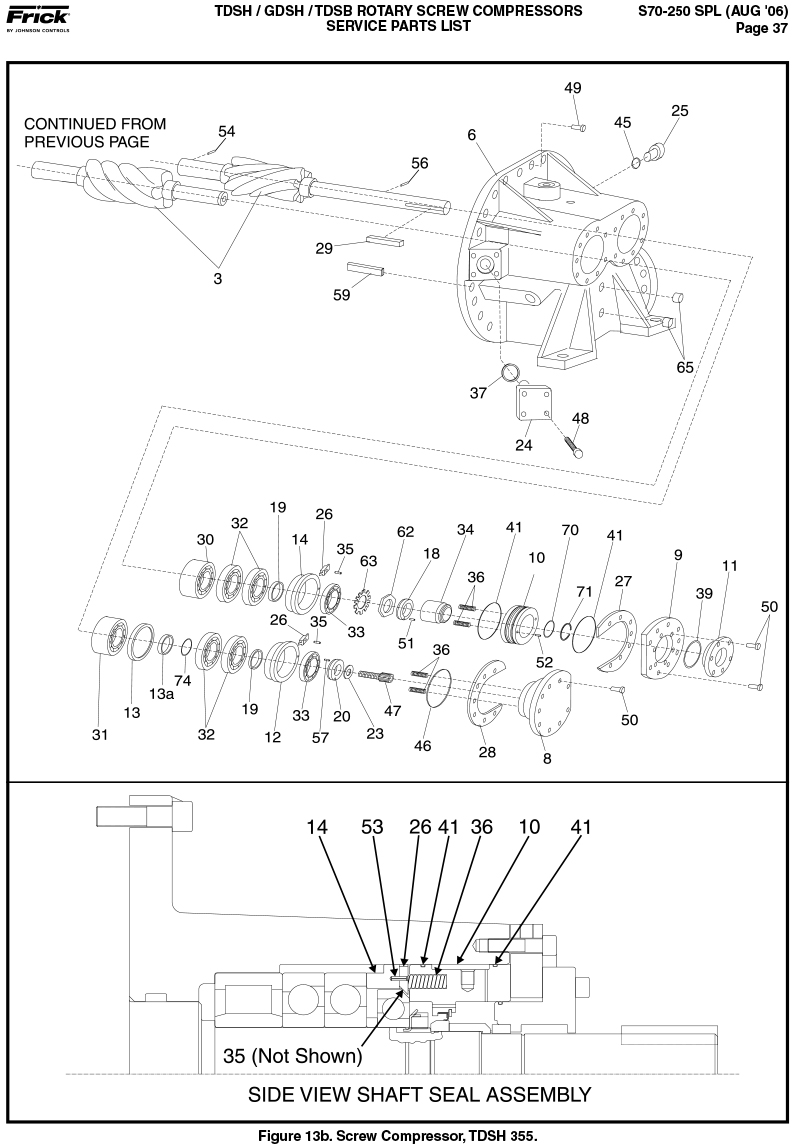

Figure 13a. Screw Compressor, TDSH 355 page..36

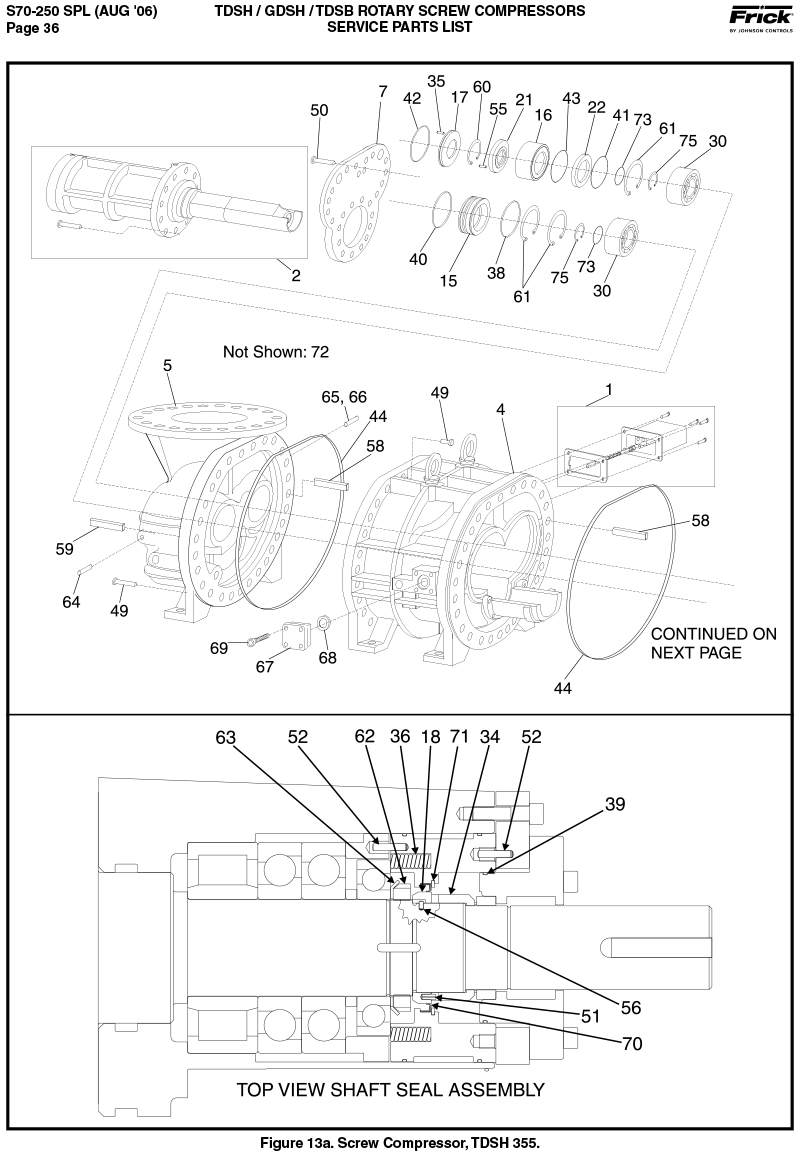

Figure 13b. Screw Compressor, TDSH 355 page..37

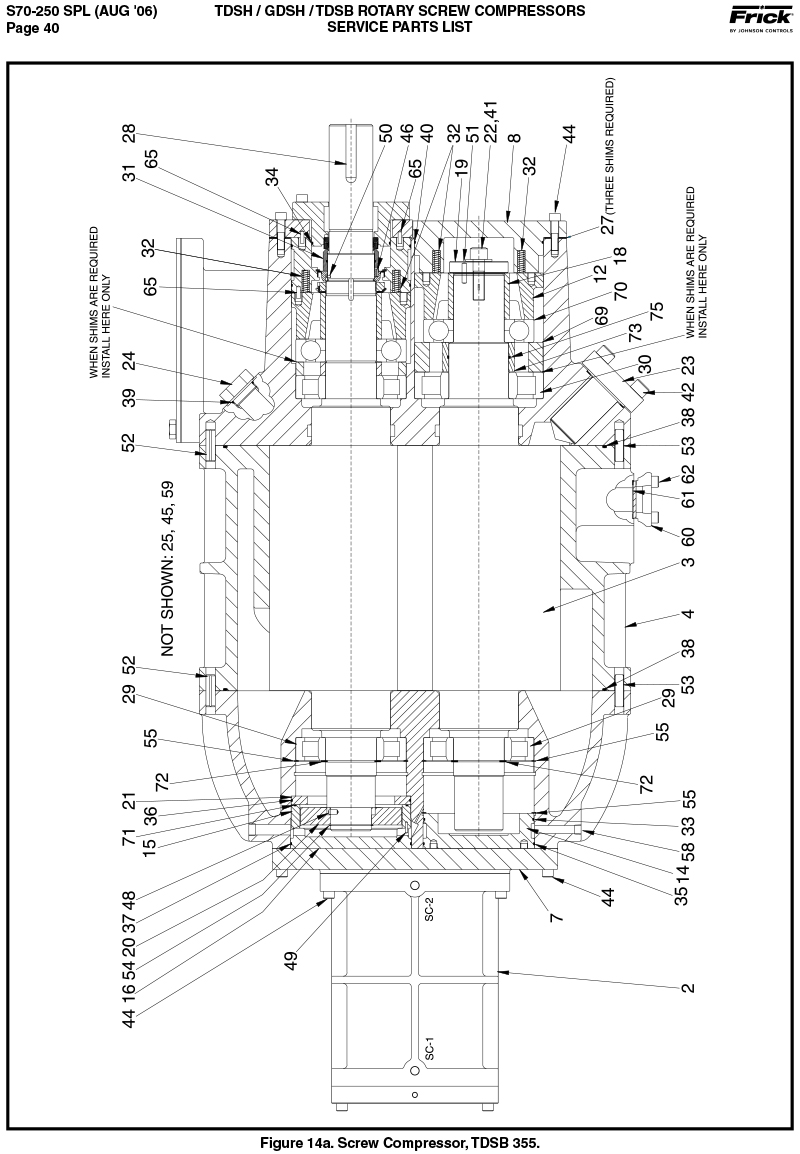

Figure 14a. Screw Compressor, TDSB 355 page..40

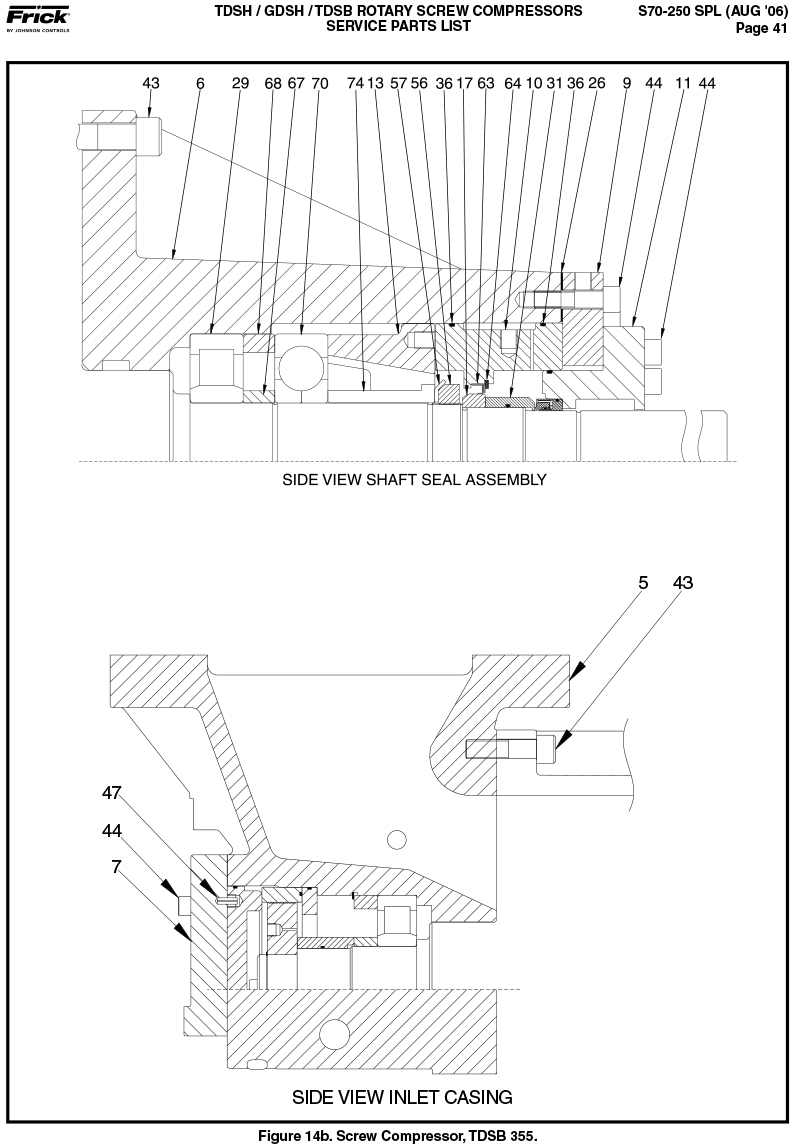

Figure 14b. Screw Compressor, TDSB 355 page..41

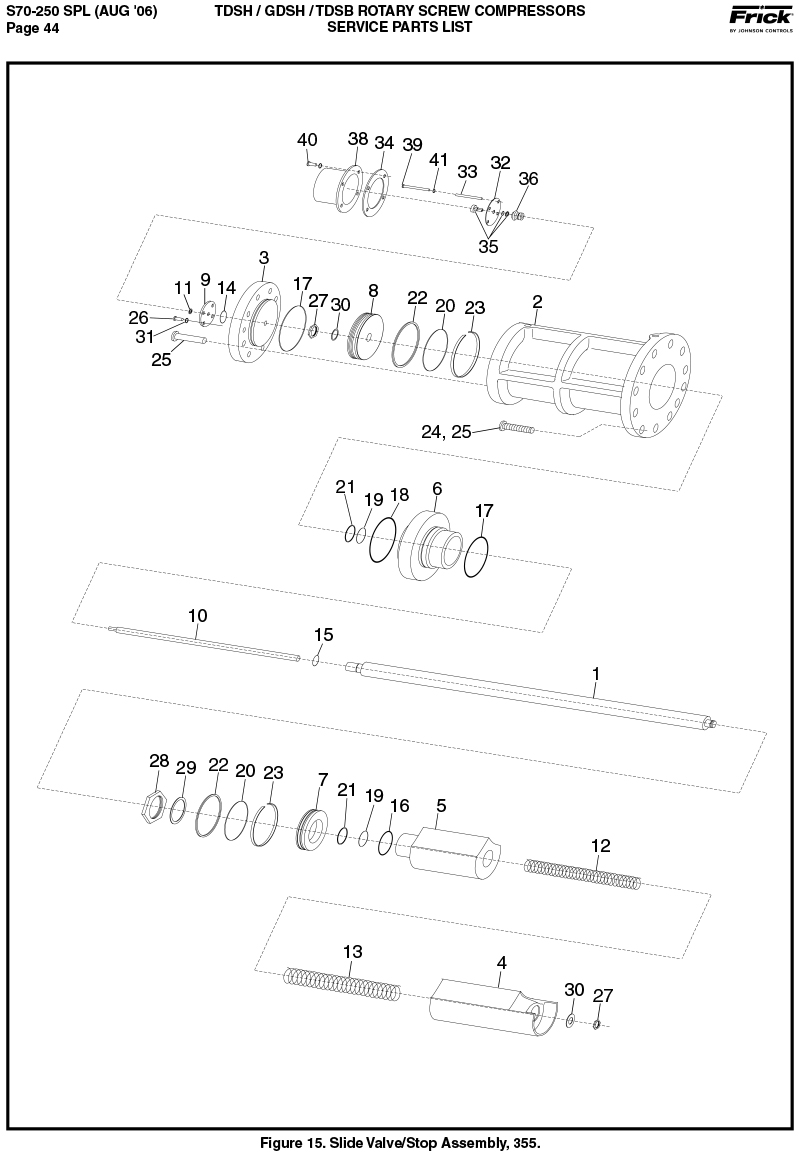

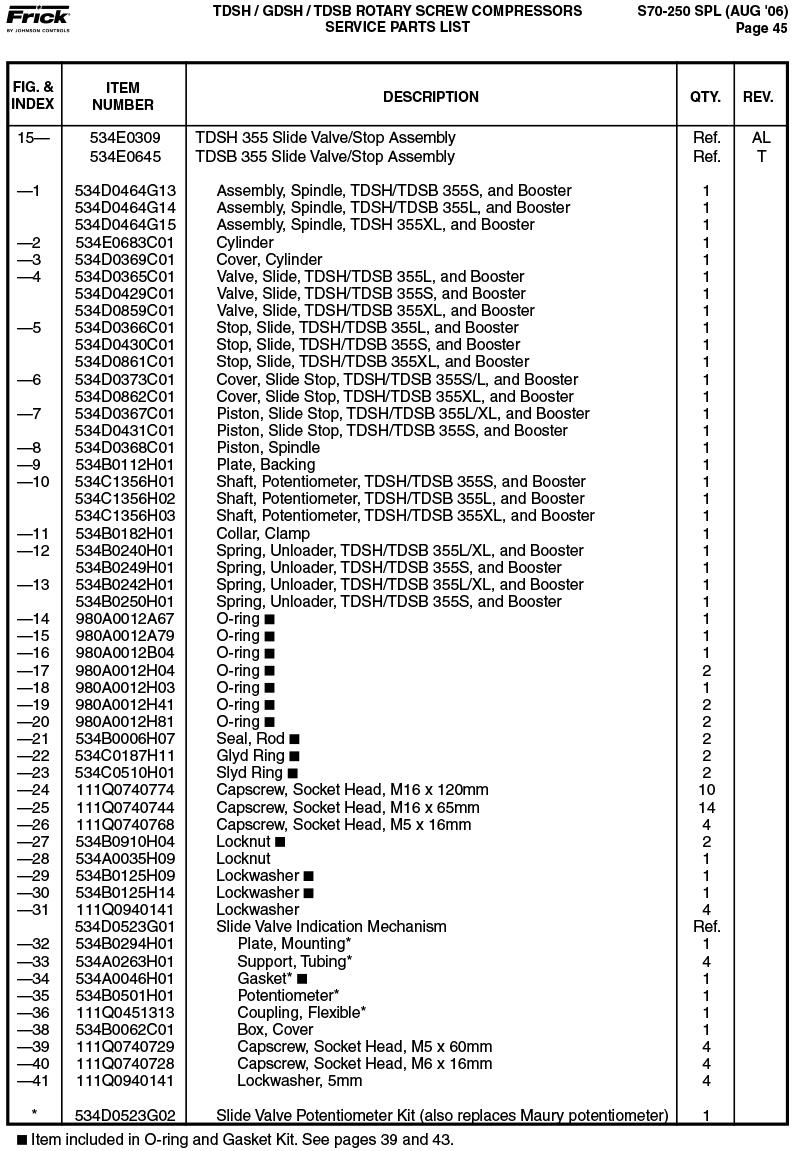

Figure 15. Slide Valve/Stop Assembly, 355 page..44

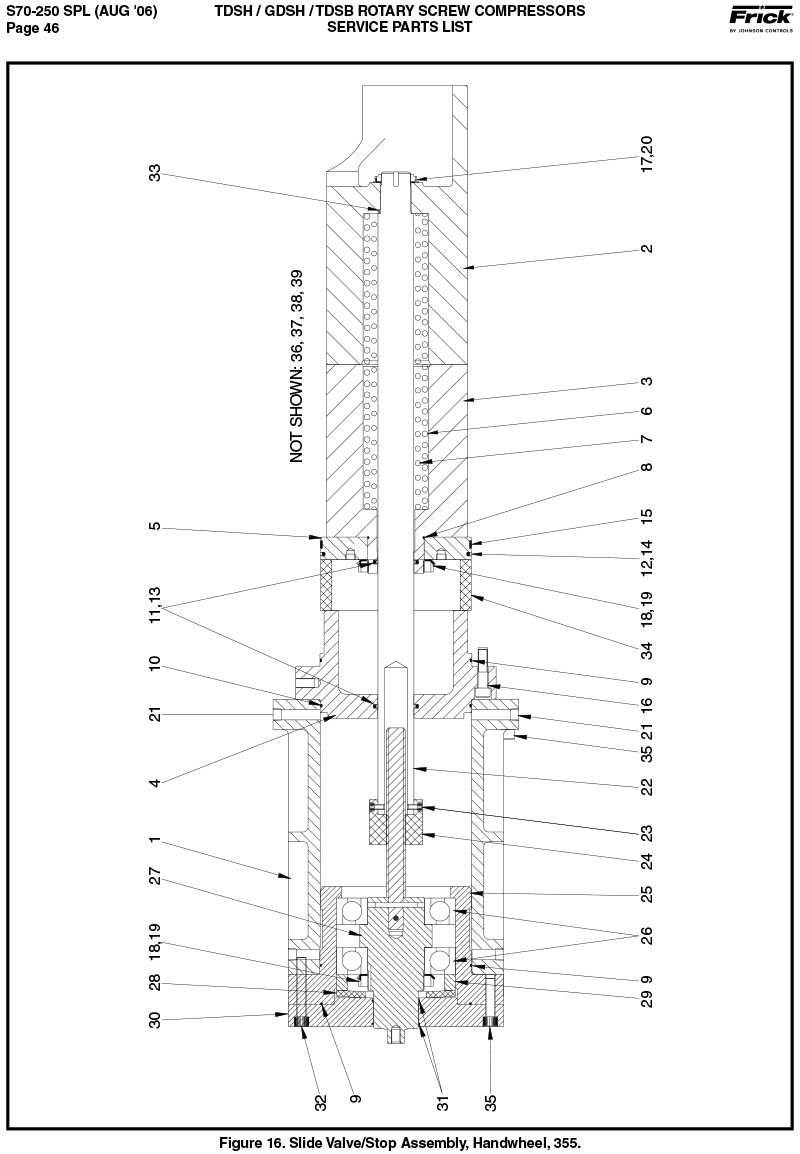

Figure 16. Slide Valve/Stop Assembly, Handwheel, 355 page..46

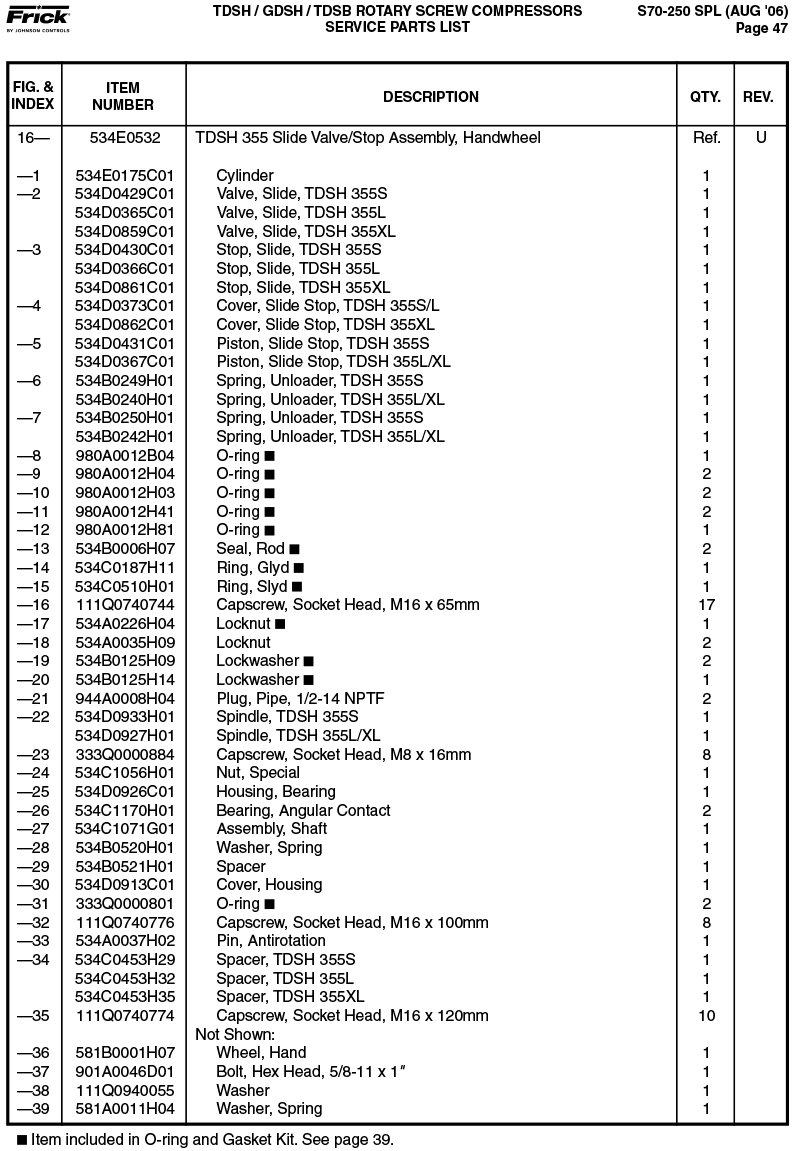

Figure 17. Slide Stop Indication Assembly, All Models page..48

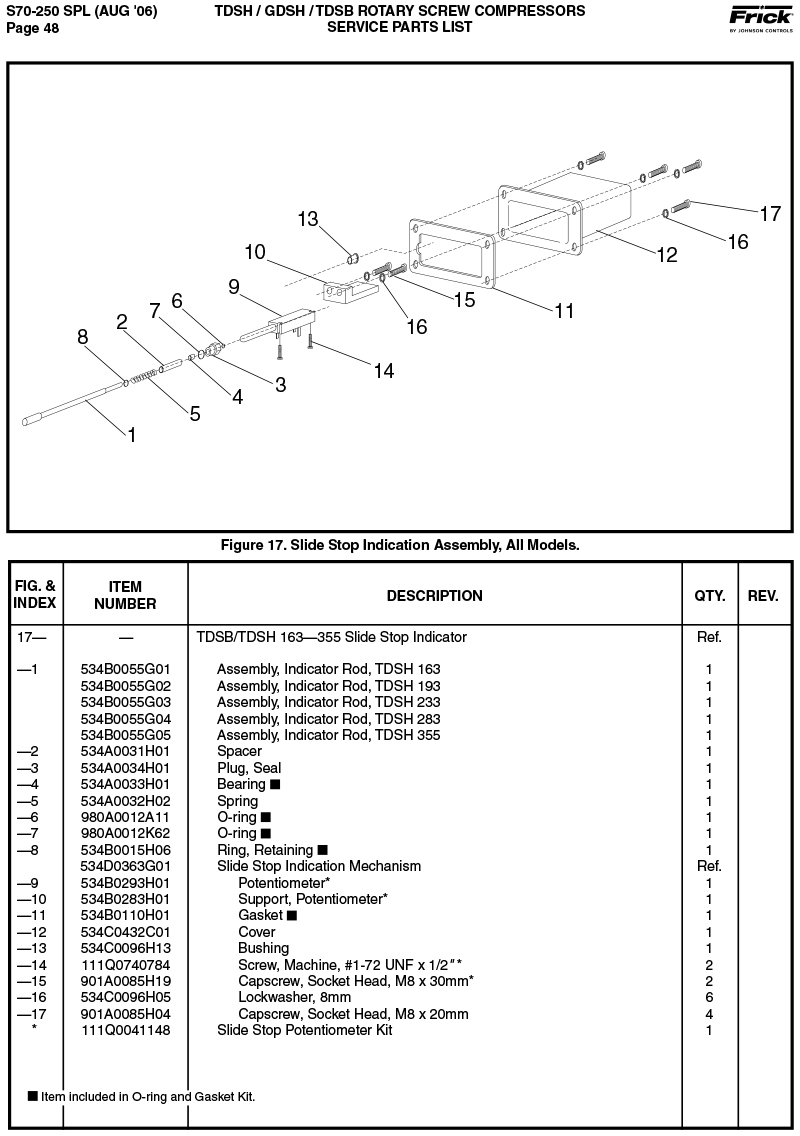

ADAPTERS - STRAIGHT THREAD TO NPTF page..49

FRICK COMPRESSOR OILS page..49

FRICK BLUE PAINT page..49

Page 3

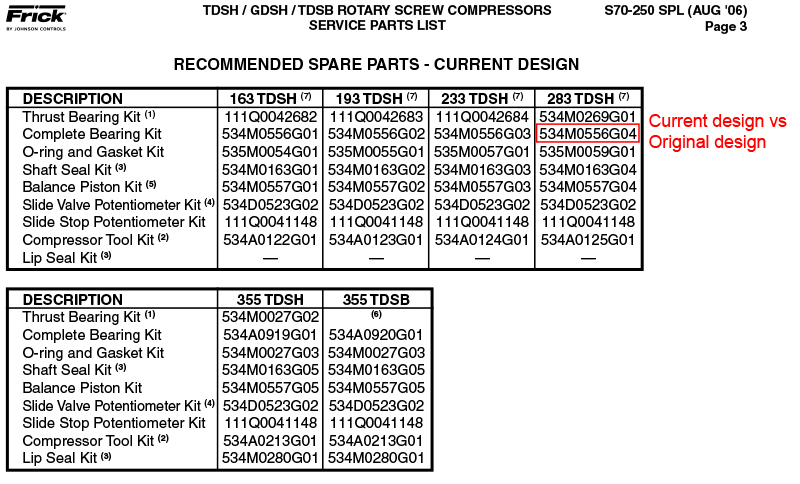

Note: When stocking the above, the quantity should be adjusted to meet your individual requirements.

(1) Current 283 TDSH Thrust Bearing Kit items are included in Complete Bearing Kit. See page 31 for serial number breaks regarding current and original kit.

(2) Master Tool Kit 534A0121G01 services all models 163 through 283.

(3) Lip Seal Kit items are included in Shaft Seal Kit. For 355 models made prior to lip seal installation (2 Janurary 1994), use Lip Seal Retrofit Kit 534D0768G01, if updating is desired.

(4) Can be used when replacing Maury Potentiometer on units shipped prior to 7/90.

(5) See page 31 for serial number breaks regarding current and original 283 TDSH Balance Piston Kit.

(6) No kit. Order two of 534B0101H28 Bearing.

(7) Parts for GDSH compressors are the same as TDSH 163-283 with the exception of the rotor housing. The GDSH has a class 300 suction flange.

Page 4

Page 5

Page 6

Page 7

Page 8

Page 9

Page 10

Page 11

Page 12

Page 13

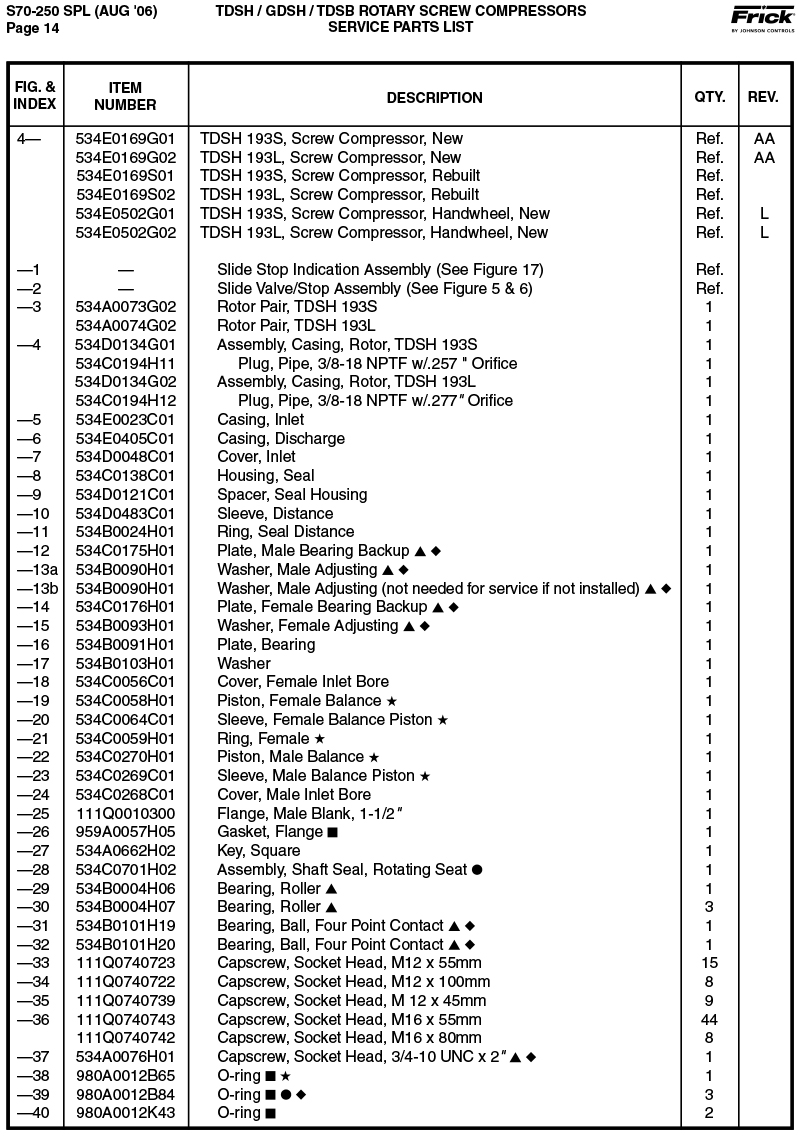

Page 14

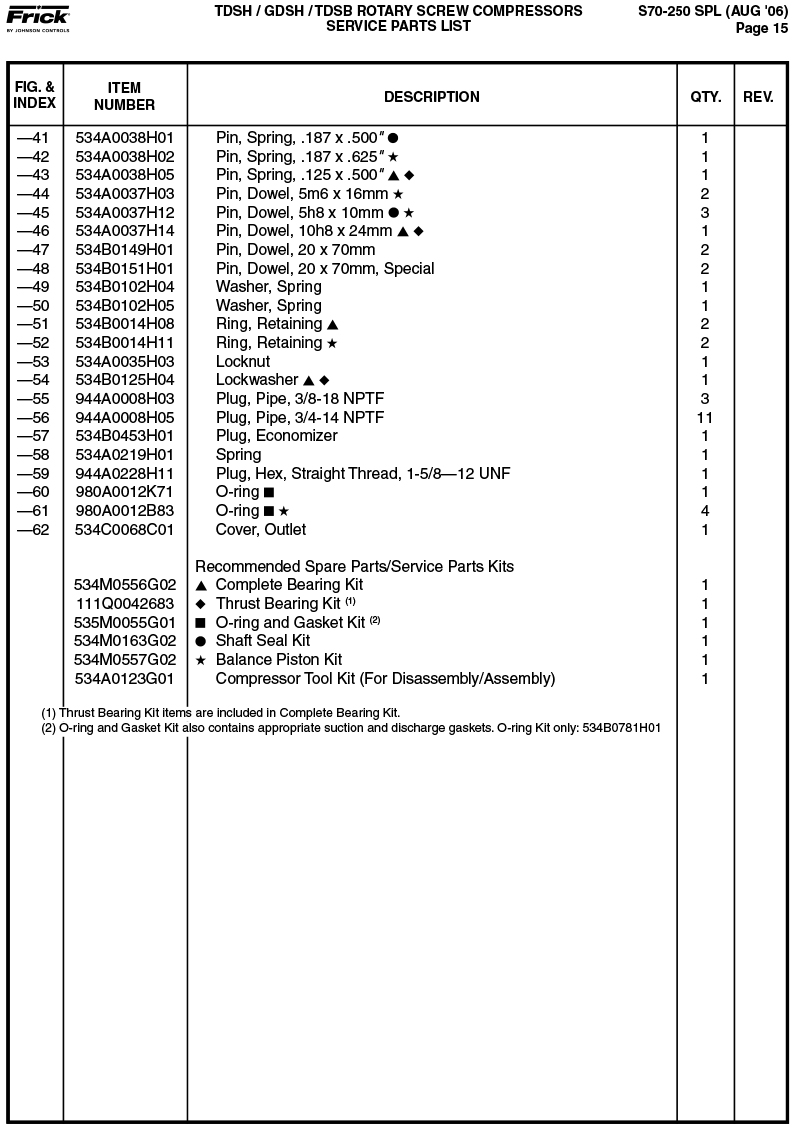

Page 15

Page 16

Page 17

Page 18

Page 19

Page 20

Page 21

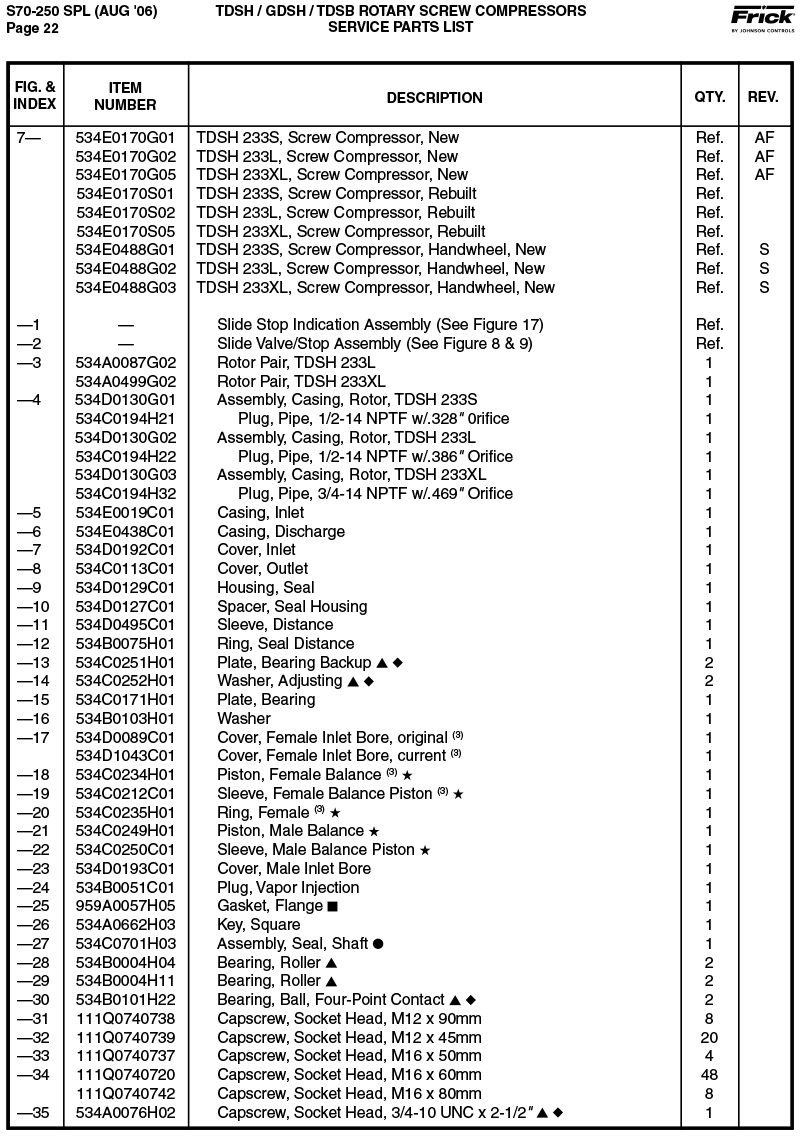

Page 22

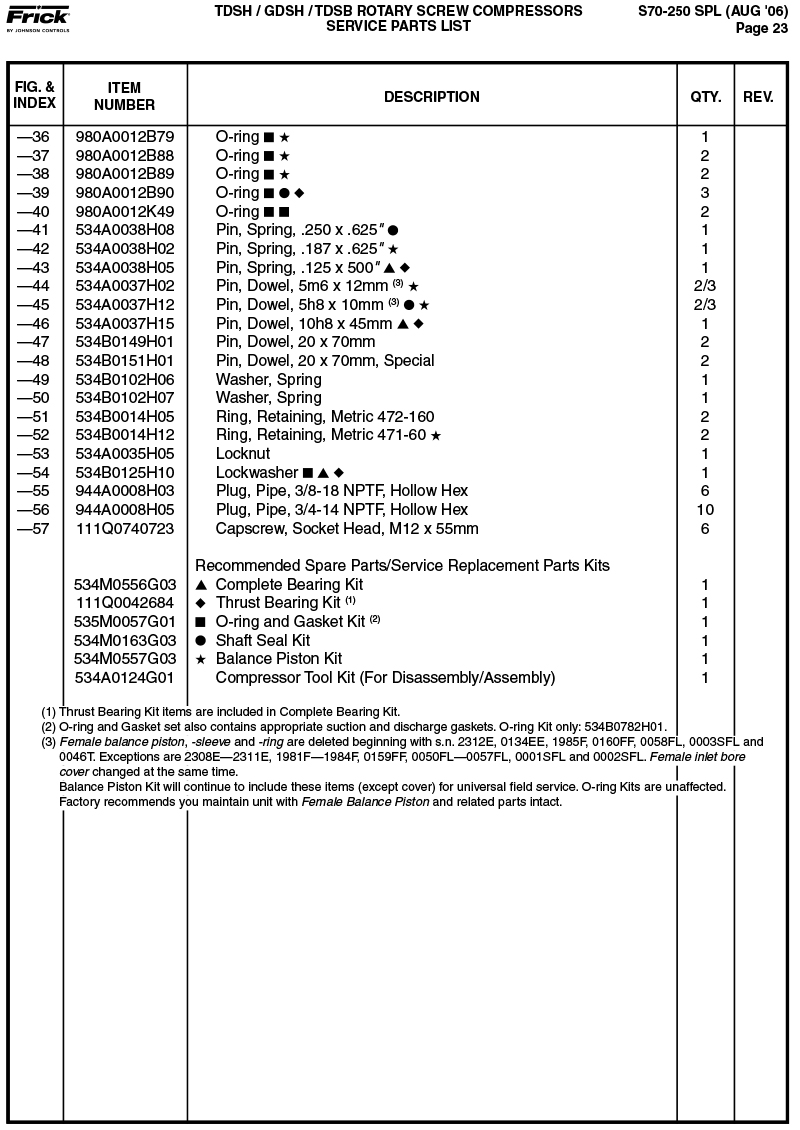

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

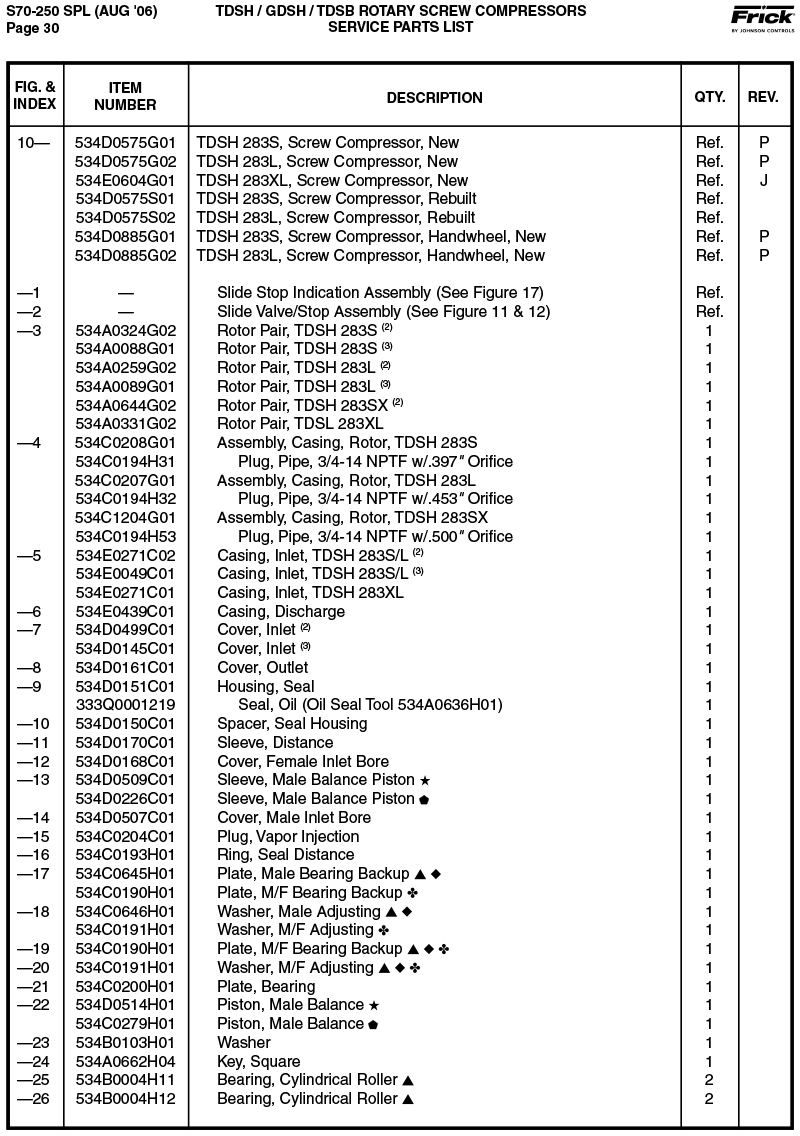

Page 30

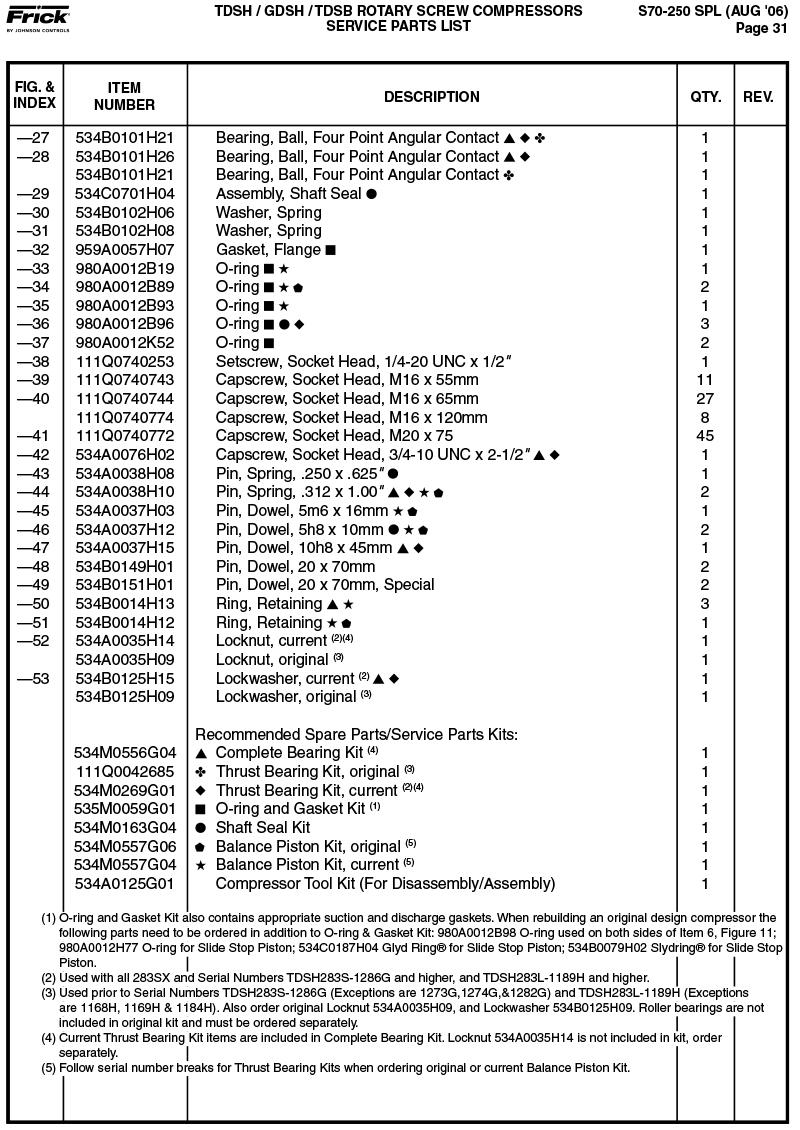

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

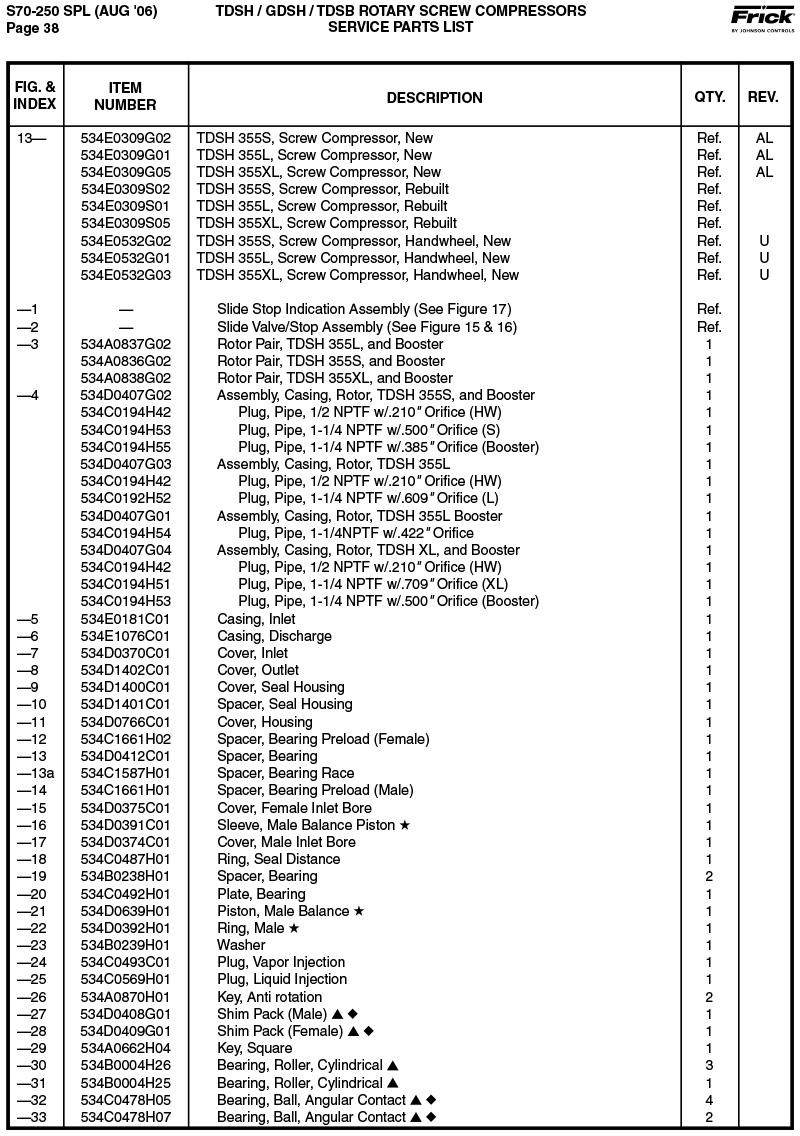

Page 38

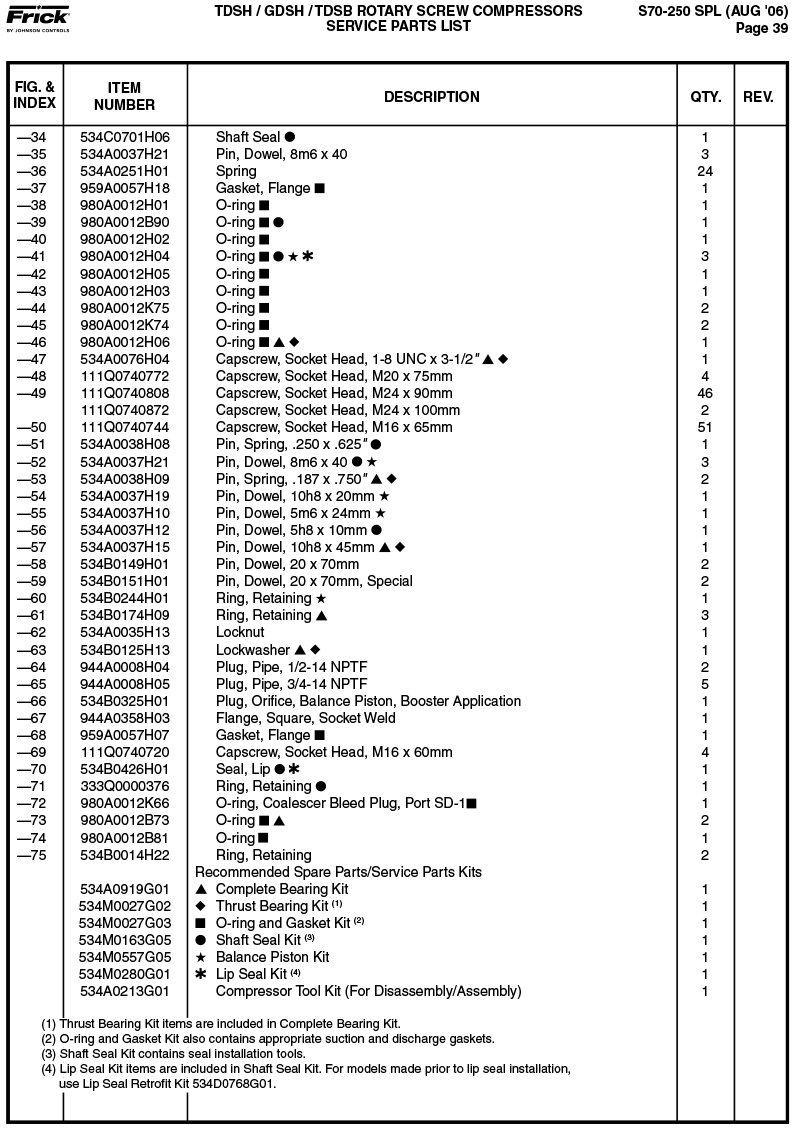

Page 39

Page 40

Page 41

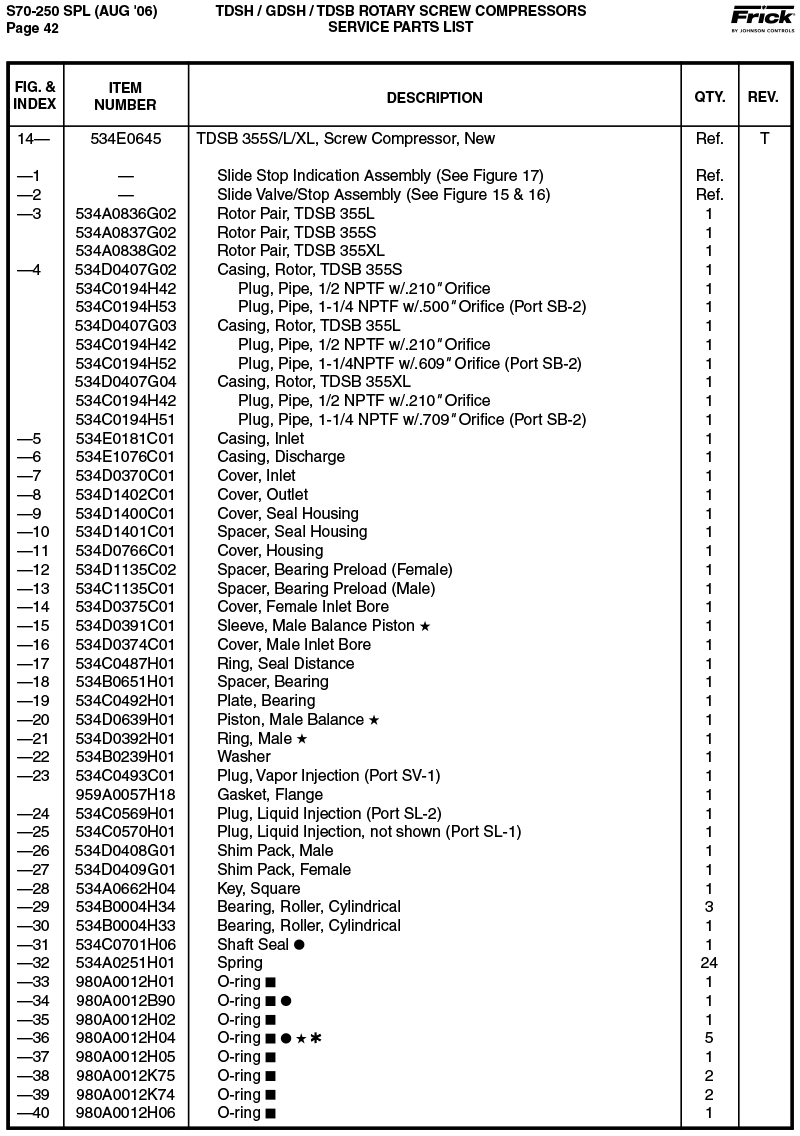

Page 42

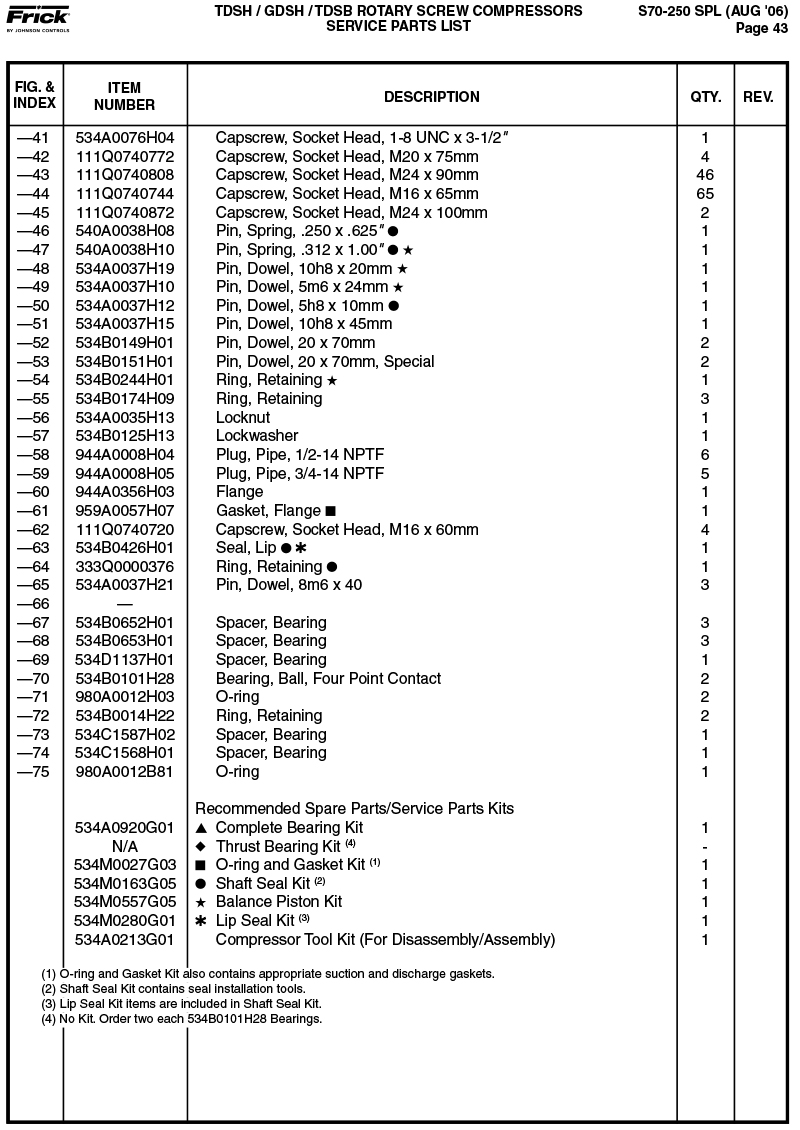

Page 43

Page 44

Page 45

Page 46

Page 47

Page 48

Page 49

Page 50

Page 51

Page 52

Page 53

Page 54

Page 55